Service

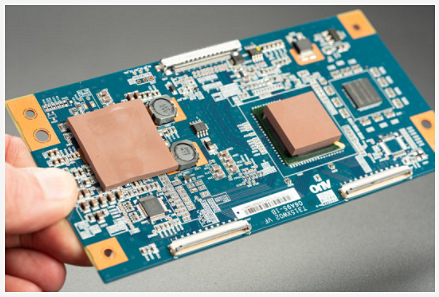

Capabilities of pcb assembly (Printed Circuit Board Assembly) services:

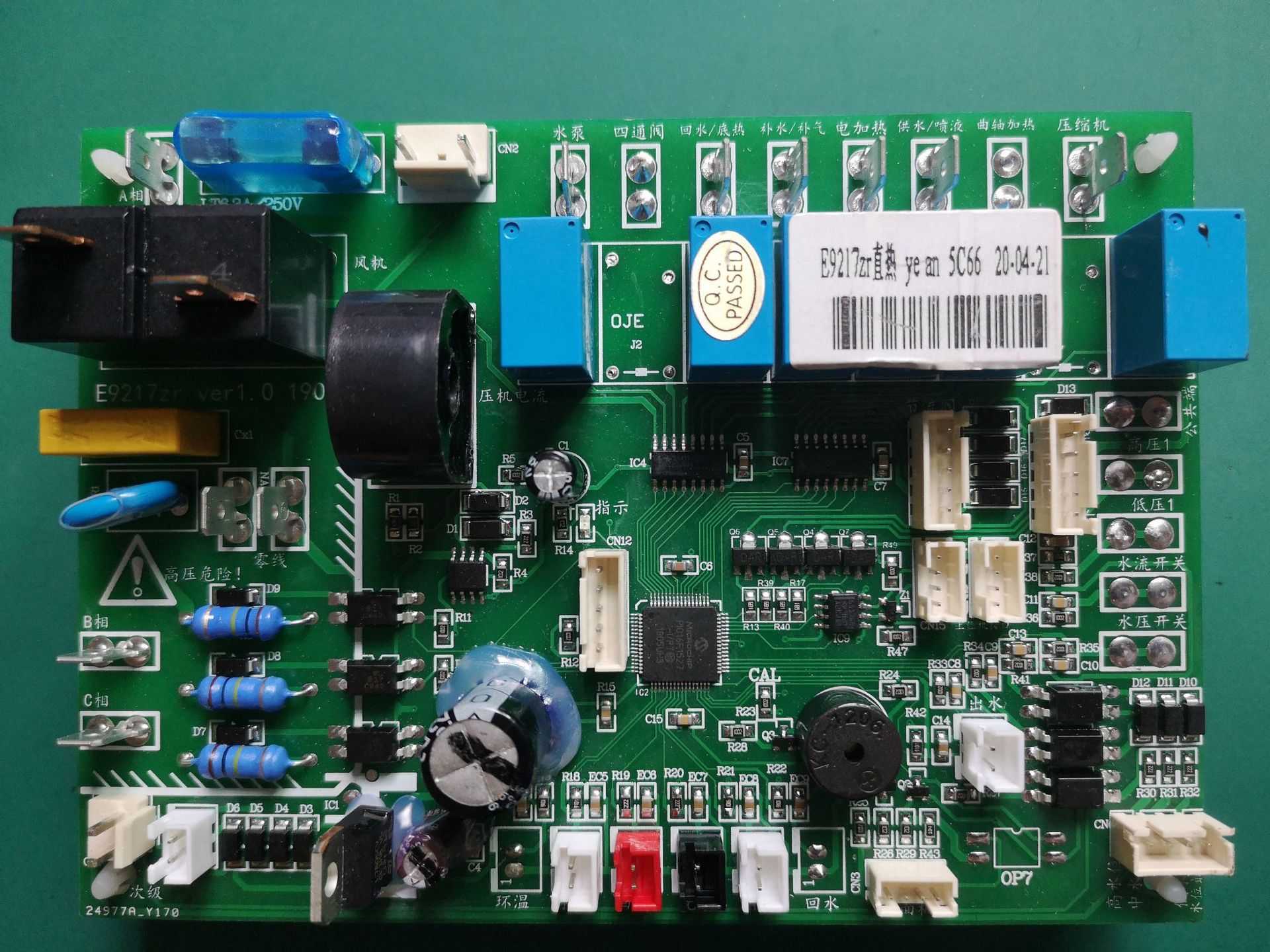

We have big capabilities for SMT/SMD assembly (also including Flexible Printed Circuit), through-hole and mixed technology PCB assemblies. BGA down to 0.25mm pitch, 0201 component placements and leadless devices assembly can also be available. High speed advanced SMT machines can well support your strict requirements of PCB assembly. In general, pass rate of soldering is up to 99.9%.

High-quality PCB Assembly and its Types.

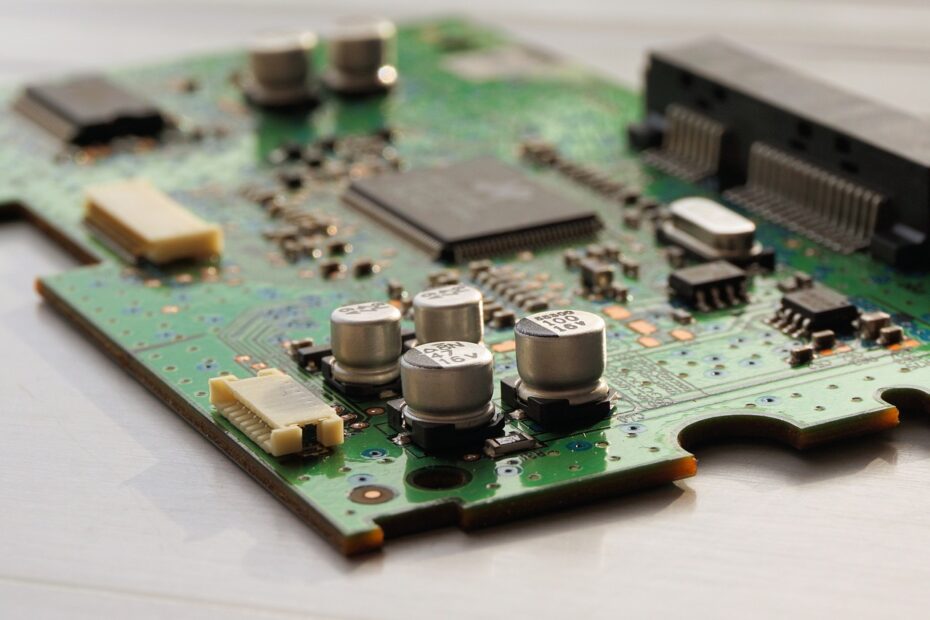

Printed Circuit Boards are panels that are found in almost all modern electronics. They are necessary, first of all, in order to provide both mechanical and electrical connection of various electronic components. To date, there are a large number of factories and enterprises that manufacture and assemble printed circuit boards.

Boards are made of a special dielectric, on which a foil pattern is applied. And already on the finished board, with the drawing correctly applied to it, the necessary electrical components are installed.

Main types of PCB mounting.

Installation of printed panels is the process of assembling the necessary electronic module, which consists of the complete connection of components and parts in the desired sequence. This ensures the interaction of all elements and their performance. Separately, it is worth noting the soldering of printed circuit boards.

This process is the joining of two or more components by so-called fusible bonding. Soldering is done using solder and flux. To prevent possible short circuits and other problems, a protective layer is preliminarily applied to the board before soldering.

There are also other types of PCB mounting:

● output;

● auto;

● surface.

Each of these types is used in different situations, depending on the type of components being installed.

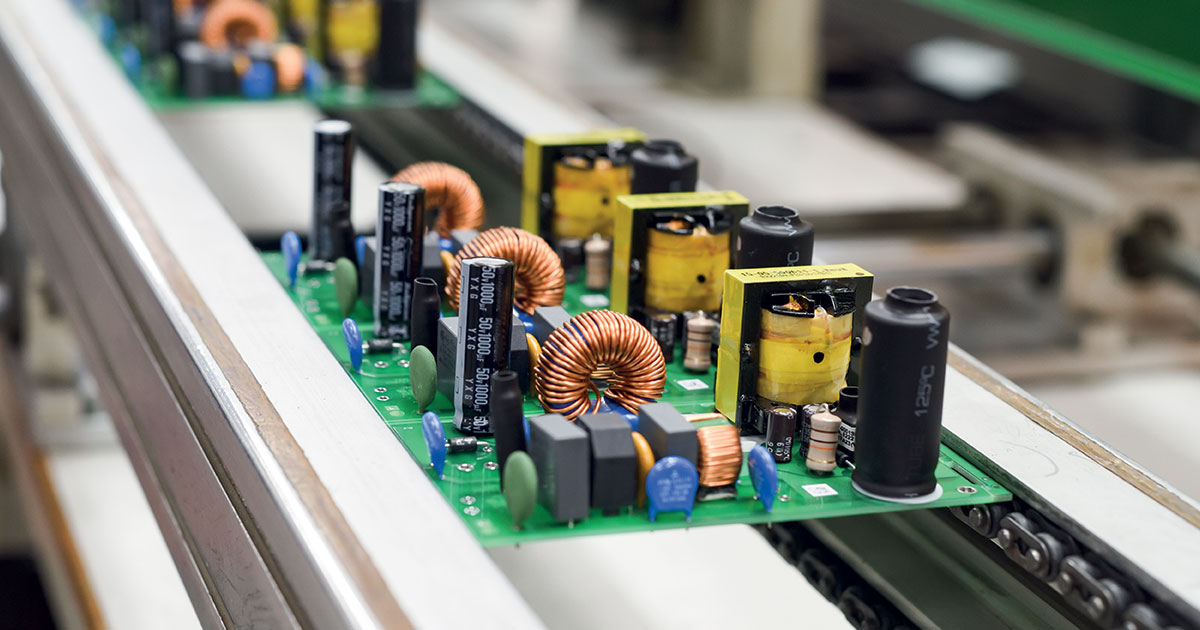

Lead-through wiring of printed circuit boards.

This type of mounting (also called DIP) is the oldest, and appeared at the same time as the printed panels themselves. It implies the assembly of a certain electronic module by installing components with their leads into the holes of the board and further soldering.

Although this type of PCB mounting has long lost its distribution, it is still impossible to do without it in the manufacture of such categories of electrical appliances as power supplies, power electronics, and the like. In addition, at the moment there are such components, the installation of which is simply impossible without the use of soldering and output wiring.

Installation of Printed Circuit Boards.

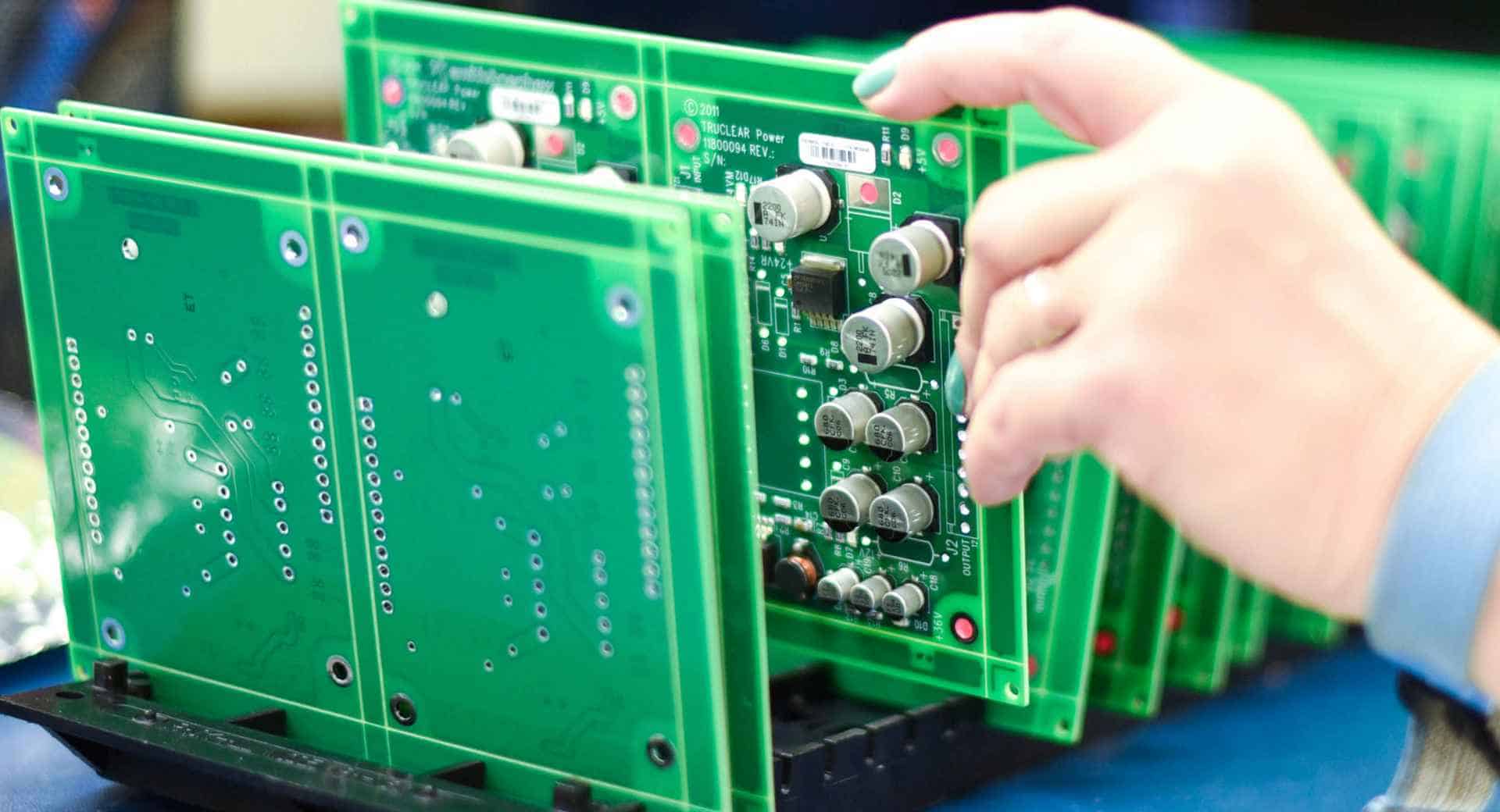

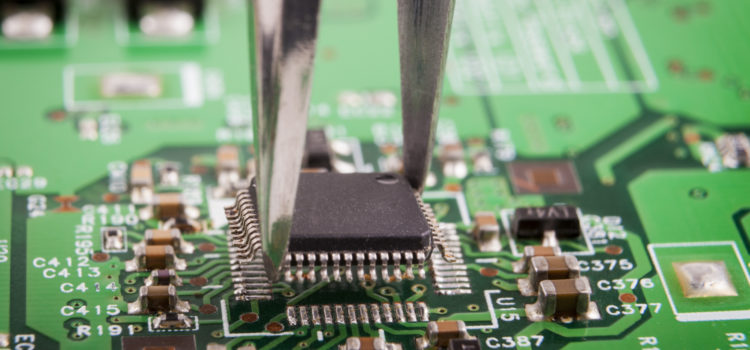

Before proceeding directly to the installation of printed circuit boards, it is necessary to prepare all the necessary components. To do this, the pigtails of all components are aligned. It should be noted that when forming conclusions, it is impossible to violate the integrity of the components or damage them.

Manual assembly of printed circuit boards is used only in cases where the use of automatic equipment is most unprofitable – if the order is very small. In addition, some boards may not be suitable for automatic installation, so manual installation will be necessary.

Automatic assembly of printed circuit boards.

Such installation of components on printed circuit boards is carried out by special expensive equipment in cases where it is advisable to use automated installation. Among the main advantages of this installation method is:

● high level of design reliability;

● a significant reduction in the cost of manufactured boards;

● automatic quality control during the installation process;

● high work accuracy even with small components;

● high speed.

In the automatic assembly of printed circuit boards, several types of soldering can be used at once – wave and selective. Wave soldering is a special type of soldering electronic components to the board, using a short time immersion of the bottom surface of the printed circuit board and the conclusions of the components themselves in the solder.

Which industries require pcb assembly services?

This technology is especially relevant in very large industries, because it allows you to process an impressive number of plates and their components per unit of time. To avoid breakage or integrity violations, a protective layer is additionally applied to the plate.

Selective soldering is a new technology that appeared only in the nineties of the last century and has the best reviews at the moment. It allows high-quality selective mounting of only output electrical components. The level of productivity of this type of installation is several times higher than that of a manual installation.

This type of soldering is financially more profitable and expedient, and due to the modern decrease in the use of output electrical components, selective soldering has become widespread. The main feature of this soldering method is that there is no need to additionally wash the boards from the flux, since it is applied pointwise.

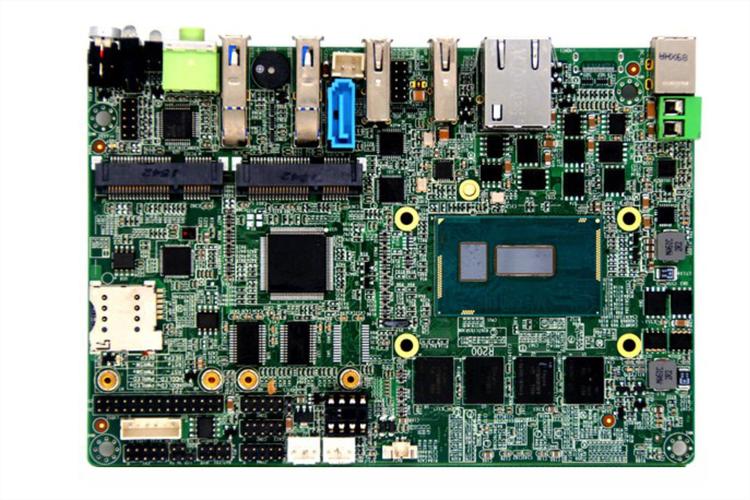

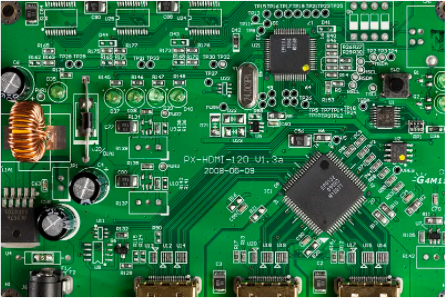

Surface mounting of printed circuit boards and components.

This type of mounting is the most progressive and is increasingly used in modern electronics. With its help, it was possible to largely automate the process of manufacturing and mounting boards, as well as their dimensions.

The main feature of this method is that the electronic components themselves (chips) are mounted on the surface of the plate only from the side that contains the conductive tracks. This eliminates the need for holes. The main advantages of this type of installation are:

● qualitative reduction in the level of initial cost;

● reducing the weight and size of the finished product;

● no need for holes for installed components;

● allows you to use two sides of the plate at once;

● increase in the density of installation of components.

However, all this requires more expensive equipment and skilled personnel for manual assembly of printed circuit boards. This type is used to install SMD components; it is the most common method of mounting printed circuit boards today.

Select Top Company for PCB Assembly in China.

Each plant for the production of printed circuit boards and their further installation today has high-quality equipment that allows you to fulfill orders of any complexity. In China, XINZHANHONG PCBA is ready to take on your pcb assembly project at an affordable price. Also, at such enterprises, it is possible to contract the manufacture of printed circuit boards and the production of circuit harnesses, loops, connectors.

Related reading:

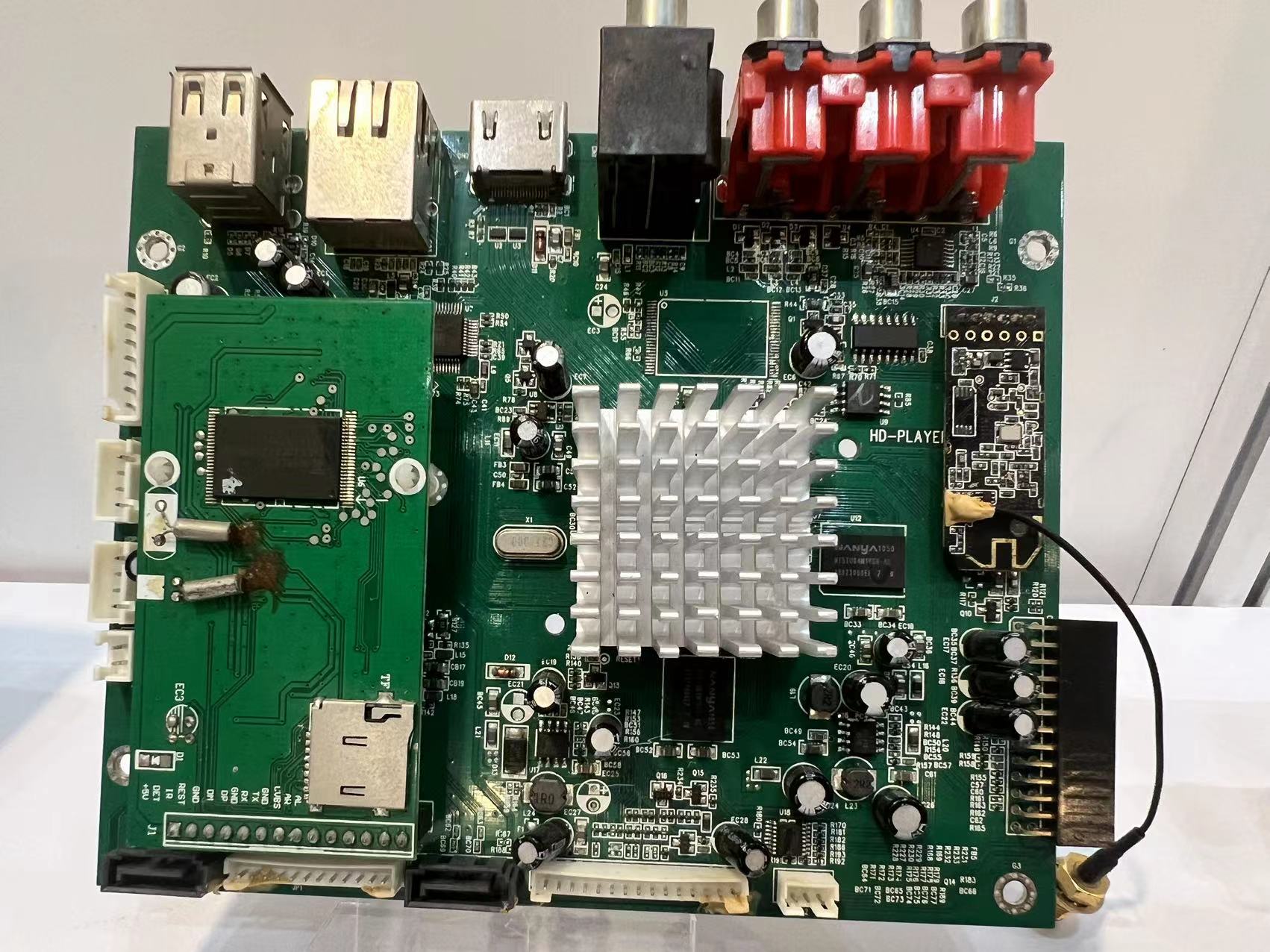

1.What is the PCBA?

PCBA = assembly of PCB.

Various electronic devices are assembled on the circuit board by a surface encapsulation process. Next is the box assembly, which assembles the assembled PCB with the outer casing to form the finished product. That is to say, the PCB bare board passes through the SMT upper part, and then passes through the entire process of the DIP plug-in, referred to as PCBA. This is a commonly used method in the country, and the standard way of writing in Europe and America is PCB’A, which adds a slant point. PCBA is the bare board with the assembly attached. For new electronic design, normally will go to prototype pcb assembly ( Sample PCBA) to verify designs. then update several time ,and go to mass production if market is good.

2.What is the difference between PCB and PCBA?

PCB refers to the bare circuit board, while PCBA refers to the circuit board plug-in assembly, SMT process. One is a finished board and the other is a bare board.

PCB(Printed Circuit Board),Made of epoxy glass resin material, it is divided into 4, 6 and 8 layers according to the number of signal layers. 4 and 6 layers are the most common. Chip components such as chips are attached to the bare board.

PCBA may be understood as a finished circuit board, and the PCBA can be made only after the process on the circuit board is completed.

3.PCBA=Printed Circuit Board +Assembly

That is to say, the bare circuit board passes through the SMT patch, and then passes through the entire process of the DIP plug-in, referred to as PCBA.

bare printed circuit board is an abbreviation for printed circuit board. Generally, a conductive pattern formed on a conductive material according to a predetermined design to form a printed circuit, a printed component, or a combination of the two is called a printed circuit. A conductive pattern that provides an electrical connection between components on an insulating substrate is referred to as a printed circuit. Thus, the finished board of printed circuit or printed circuit is called printed circuit board, also known as printed board or bare printed circuit board.

Standard PCB have no parts on the top and are often referred to as “Printed Wiring Boards (PWB).”

Xinzhanhong is a professional Printed Circuit Board Manufacturing and assembly factory, providing one-stop PCBA customization service for customers.

Related articles

PCB Clone (PCB Copy)

Find a PCB Clone (PCB Copy) company and Supplier. Choose Quality pcb clone company , Suppliers, Exporters at xzhpcba.com.You have a physical electronic circuit board on-hand but do not have...

SMT(Surface Mount Technology)

SMT is "Surface Mount Technology" in English and "SMT technology" in Chinese, which is relative to the traditional THT (Through Hole Technology) "through-hole plug-in technolo...

PCBA prototype services

Our PCBA prototype services allow you to verify & upgrade design with quick-turn of 3~7 days and low cost. The circuit boards will go through same manufacturing process and quality control. Custom...

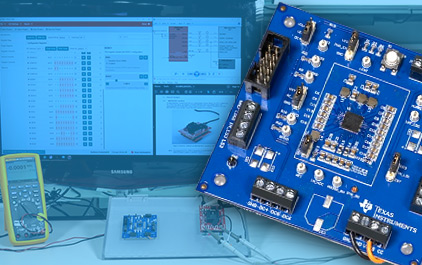

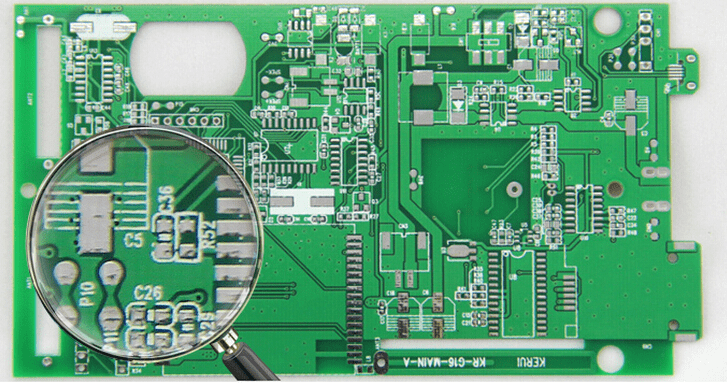

Printed Circuit Board Testing (PCB Testing)

Printed Circuit Board Testing and InspectionInspection and testing are essential aspects of bringing a product to market. A persistent failure or recall issue can not only cost you money, but can also...

PCB Manufacturing(Printed Circuit Board Manufacturing)

PCB MANUFACTURING (Printed Circuit Board Manufacturing)XINZHANHONG is the leading PCB manufacturer based in Shenzhen, China. We have over 10 years of experience in providing advanced PCB manufac...

IC Programming

IC programming is the process of transferring a computer program into an integrated computer circuit. Older types of IC include PROMs and EPROMs.PCBA processing technology has become increasingly matu...