Service

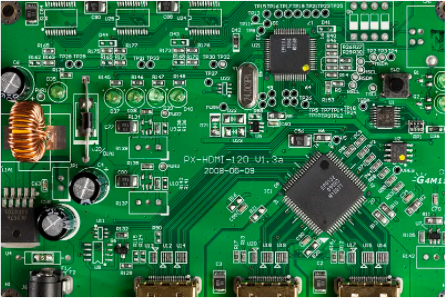

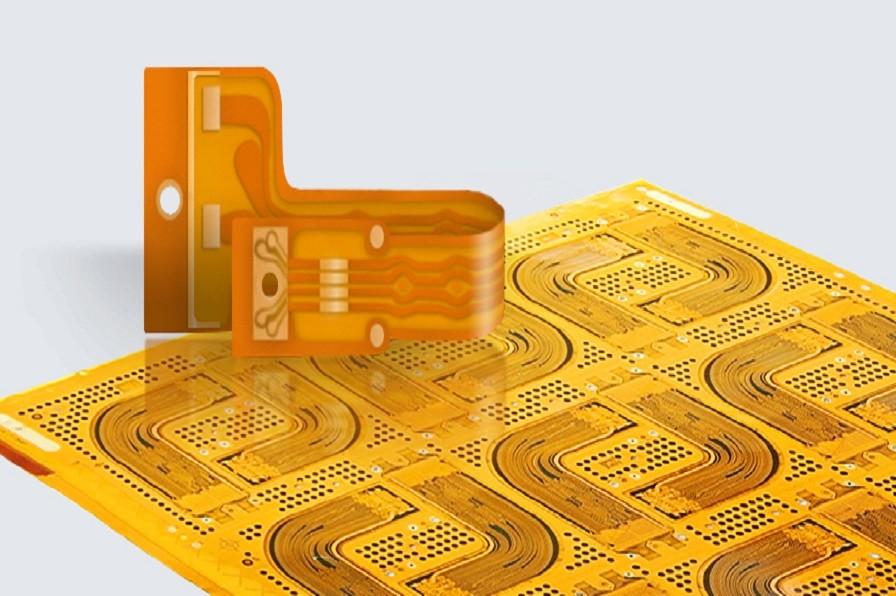

SMT is "Surface Mount Technology" in English and "SMT technology" in Chinese, which is relative to the traditional THT (Through Hole Technology) "through-hole plug-in technology". The carrier for implementing SMT or THT is a circuit board. "Surface" refers to the bonding pad on the PCB surface that can be used to print solder paste, and "through-hole" refers to the plated through-hole PTH on the circuit board SMT patch is a more efficient and advanced electronic welding technology than THT plug-in.

Advantages of XZH SMT.

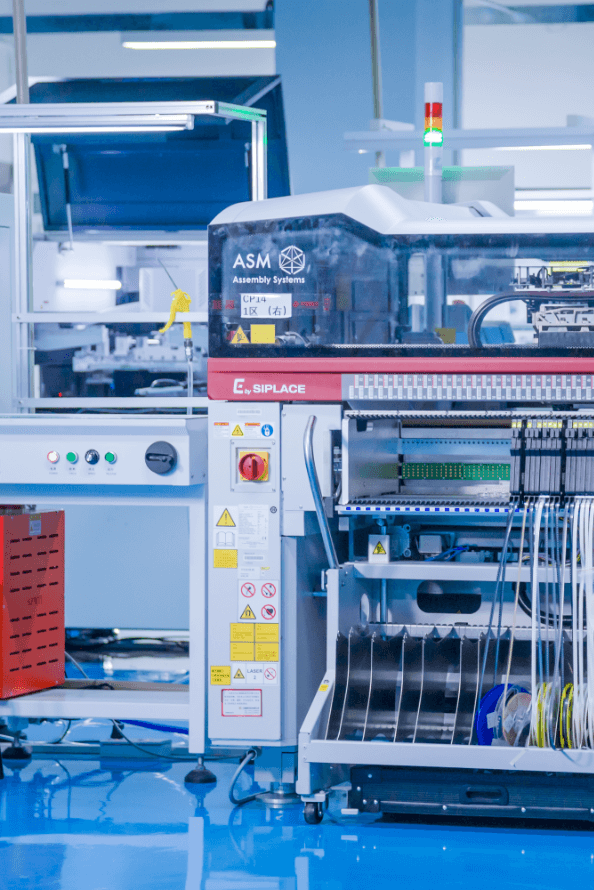

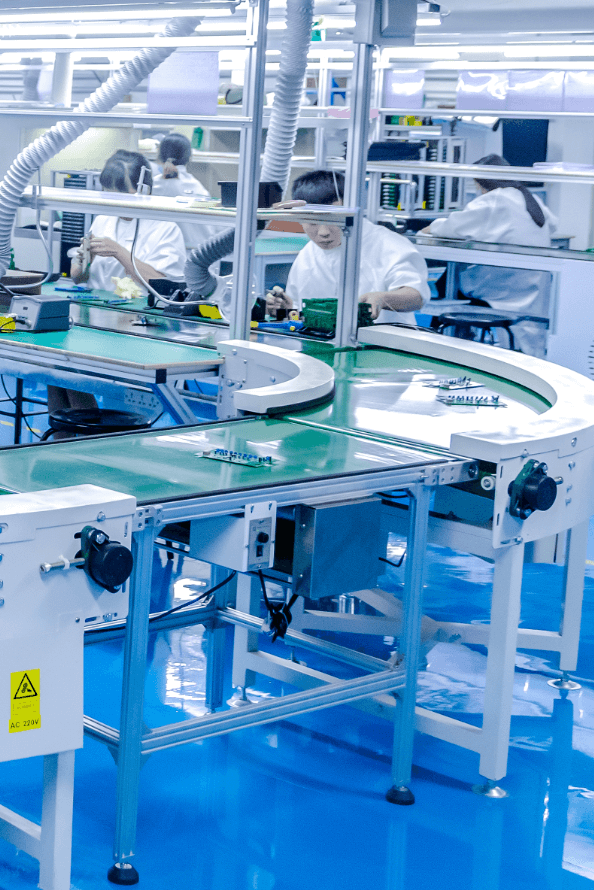

XZH's SMT chip processing plant is equipped with advanced equipment, such as the automatic solder paste printing machine of Denson, the high-speed and multi-function chip mounters of Samsung or Panasonic, and 50% of the employees have more than five years of SMT processing experience and precision detection instruments, such as the SPI (solder paste detector) of Stark, the first article detector (FAI), the quasi stable AOI and the X-ray of Shimadzu, Japan. The daily SMT production capacity of the four SMTs can reach 3 million points, which can fully meet the production and quality requirements of general customers in terms of equipment, instruments and capacity. The PCBA industry needs to have a strong overall technical strength. Process technology, quality control level and production management technology are very important and require long-term practice and accumulation. A brief summary is as follows:

(1) 4 fully automated SMT production lines and DIP production lines, high-capacity and high-precision equipment;

(2) Professional manufacturing team, operators have years of work experience and regular training;

(3) It is suitable for high-end manufacturing and provides channels for the production of high-end products of small and medium-sized enterprises. At the same time, it can save 20% of the cost compared with other processors.XZH's SMT quality control.

Compared with pcb production process and equipment configuration, SMT processing is much simpler. Simply understood, it means printing solder paste and checking the printing status of solder paste, high-speed machine pasting of small electronic components, multi-function machine pasting of large electronic components, AOI detection of patch status (commonly called "furnace front detection" in the industry, "furnace" reflow soldering furnace), over reflow soldering curing, AOI furnace rear detection, and finally visual inspection. SMT chip processing seems simple, but we dare not slack off in quality control. XZH mainly ensures the quality of SMT chip processing from the following aspects:

(1) Use the well-known solder paste of Qianzhu or Loctite, print it with an automatic solder paste printer and detect it with a solder paste detector to ensure that 80% of the conventional quality problems in SMT processing are effectively controlled in this link;

(2) Use an advanced first article detector to detect the first article and issue a first article inspection report;

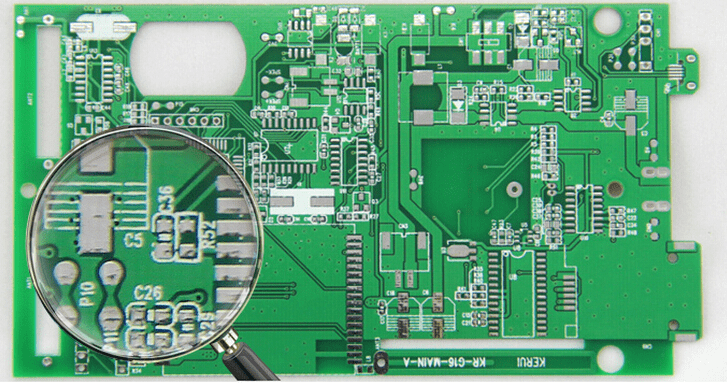

(3) AOI automatic optical detector detects pasted components in front of and behind the furnace to ensure that large and small components are not missed, wrongly pasted, biased or reversed;

(4) PCB boards with BGA shall be spot checked with X-ray after mounting or fully inspected according to customer requirements.XZH's process capability.

Project

Process capability

SMT Patch Equipment

GKG/Panasonic/JT

Tin paste printing accuracy

±0.025mm

Element mounting precision X, Y

±0.03mm Cpk≥1

Minimum element mounting angle

0.01°

Mount the substrate size

50×50 mm~750×550 mm

Available for component dimensions

03015 Chip: ~ 12,090 mm

BGA ball spacing

0.25mm~2.0mmm

The BGA ball diameter can be mounted

0.1mm~0.63mmm

Material loss rate

Class IC zero loss / resistance capacity class 0.3%

Reflow-flow welding temperature control precision

±1℃

Detection device

SPI/AOI/X-RAY

SPI Detectable items

Volume, area, height, XY offset, shape

SPI mainly detected poor types

Leakage, tin, tin, tin, offset, bad shape

The SPI detects the minimum detection element

01005 (British system)

The SPI can detect the accuracy

XY direction <10um; Height =0.37um

The SPI can detect the reproducibility accuracy

Height <1um (4sigma); area / volume <<1% (4sigma)

The AOI detects a minimum part test

8um:01005chip &0.3pitch IC

A major coverage type of AOI detection

Offset, less tin, short circuit, more tin, missing parts, skew, standing monument, side stand, turn over, wrong Parts, damage, polarity, virtual welding, empty welding, glue overflow, tin hole, pin is not out of the appearance good people.

X-RAY image enhancer resolution

75/110lp/cm

The X-RAY amplification was performed in the

420×

X-RAY detects X-ray tube focusing

5um

Xinzhanhong is a professional Printed Circuit Board Manufacturing and assembly factory, providing one-stop PCBA customization service for customers.

Related articles

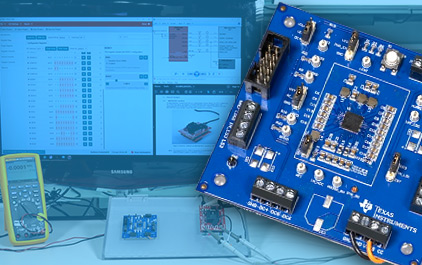

Printed Circuit Board Testing (PCB Testing)

Printed Circuit Board Testing and InspectionInspection and testing are essential aspects of bringing a product to market. A persistent failure or recall issue can not only cost you money, but can also...

Parts Procurement

Well-established, effective component sourcing system for low-cost PCB Assembly. We have strategic well-established supply partners and with these partnerships, we deliver reliable supply chain soluti...

Quick Turn Prototyping

XZH offer Quick Turn Prototyping services .When you’re developing a new design and need working prototypes in hand quickly, XZH quick-turn prototype process will get you there on time.We have rich exp...

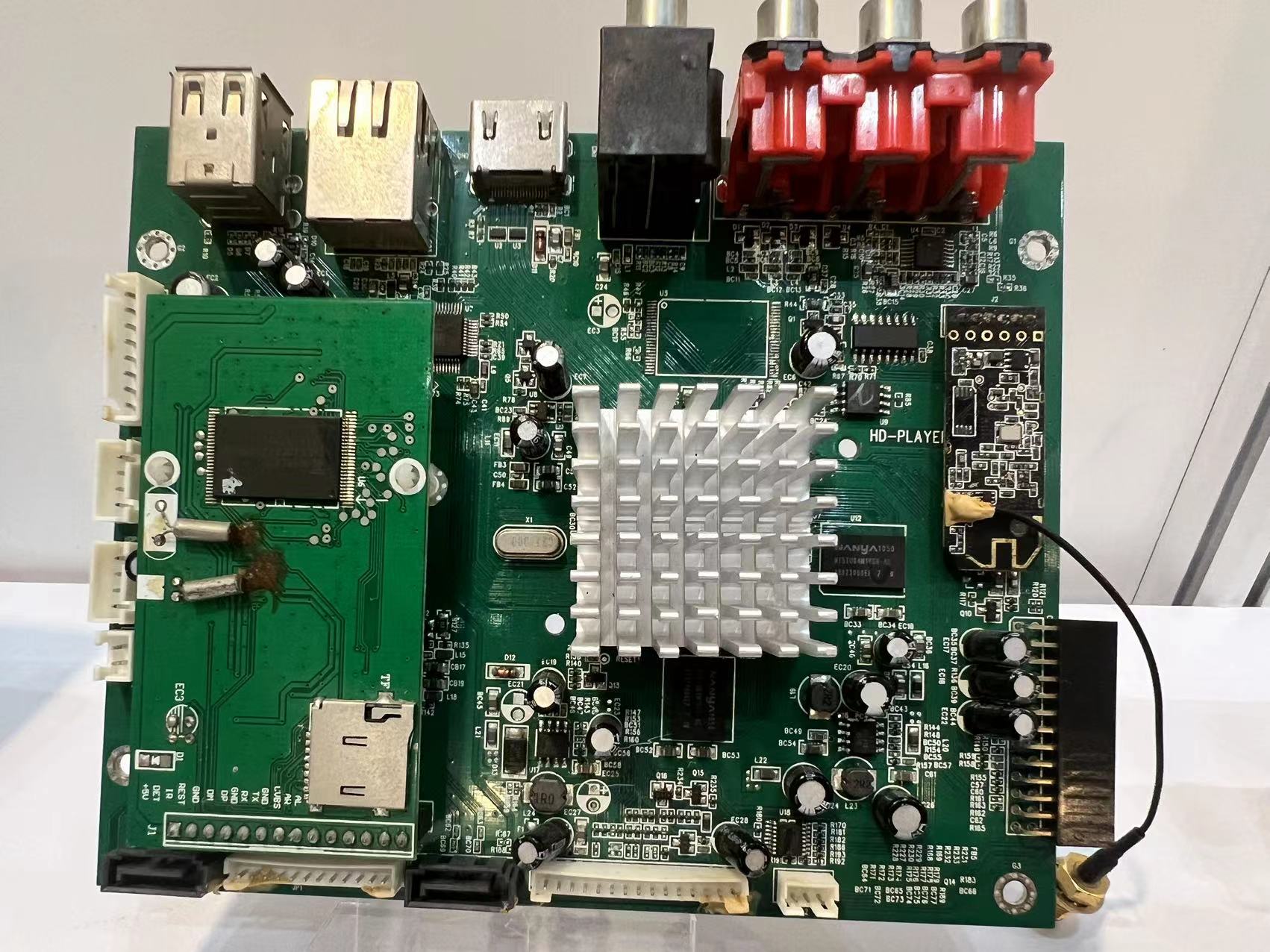

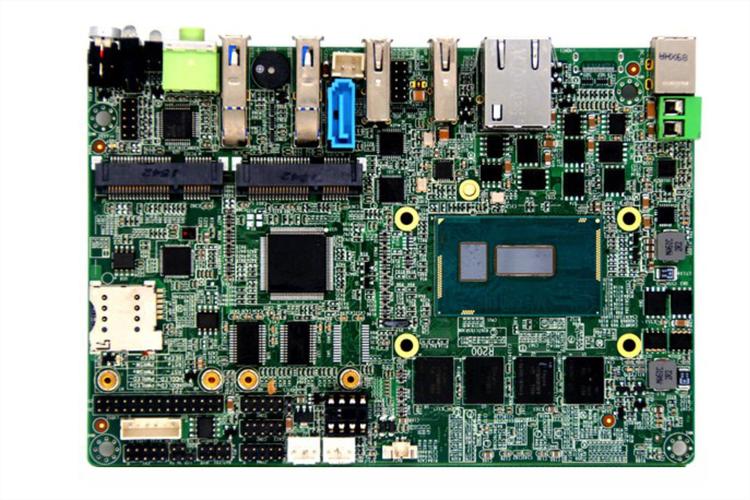

PCB Assembly (Printed Circuit Board Assembly)

Capabilities of pcb assembly (Printed Circuit Board Assembly) services:We have big capabilities for SMT/SMD assembly (also including Flexible Printed Circuit), through-hole and mixed technology PCB as...

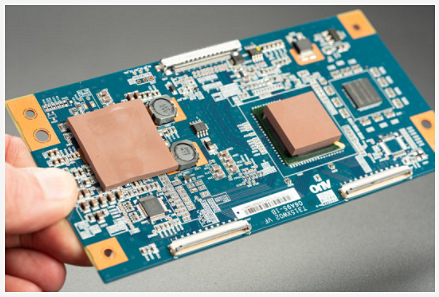

PCB Clone (PCB Copy)

Find a PCB Clone (PCB Copy) company and Supplier. Choose Quality pcb clone company , Suppliers, Exporters at xzhpcba.com.You have a physical electronic circuit board on-hand but do not have...

PCB Manufacturing(Printed Circuit Board Manufacturing)

PCB MANUFACTURING (Printed Circuit Board Manufacturing)XINZHANHONG is the leading PCB manufacturer based in Shenzhen, China. We have over 10 years of experience in providing advanced PCB manufac...