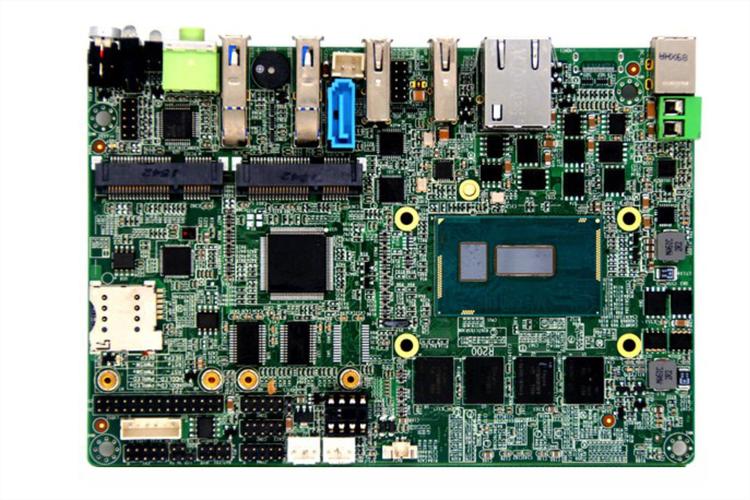

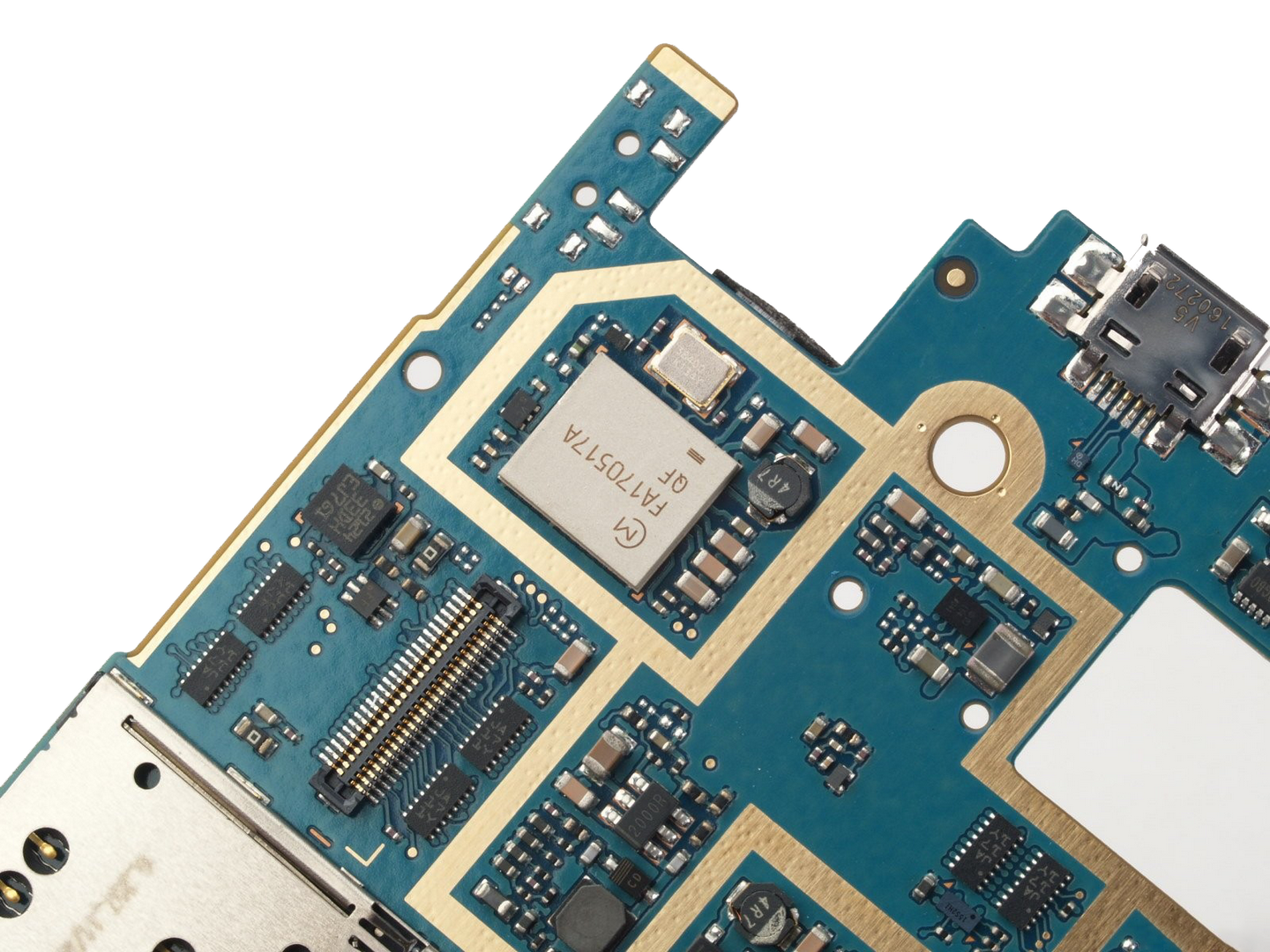

Printed Circuit Board Assembly

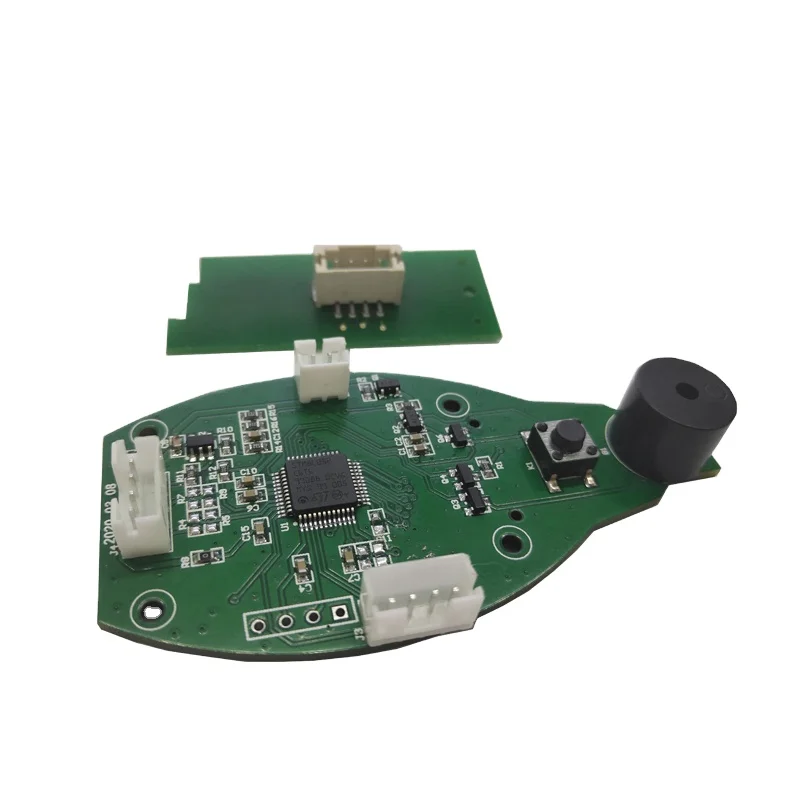

Application Case of MedICal Equipment PCBA:

Glucometer

Electrocardiograph

Heart Monitor

Temperature Monitor

CT Scanning Systeam

Transfusion Pump

Sphygmomanometer

Magnetic resonance imaging (MRI) scanning system

X-ray computed Tomography (CT) scanning system

Digital cell counting device

Heart pacemaker analyzer

Ultrasound equipment

Laser therapeutic instrument

Fluid Level Controls

Digital temperature monitor

Ear, nose and throat (ENT) diagnostic instrument

Ect.

Shenzhen Xinzhanhong Technology can custom the pcbA base on your need!

Related articles

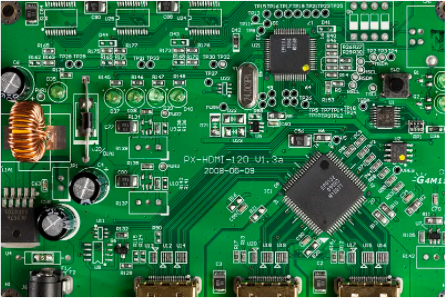

Good package for your PCBA

The circuit board is not like other products, it can not touch with wet air and water. When packing, a layer of bubble film should be wrapped around the side of the box. The water absorption of...

How to get a PCBA?

How to get a PCBA?Professional Printed circuit board manufacturing is an important step in bringing your products to the market.Preparing files for PCBAYou will need a collection of different files in...

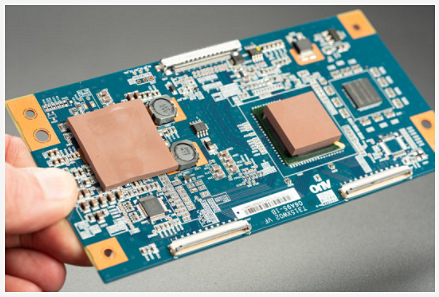

Fpc Printed Circuit Flexible Pcb

One-Stop OEM ServiceIf desired, we will source, organize and manage all aspects of the PCB design, so that your product meets all required standards and is fully optimized for easy and cost-effective...

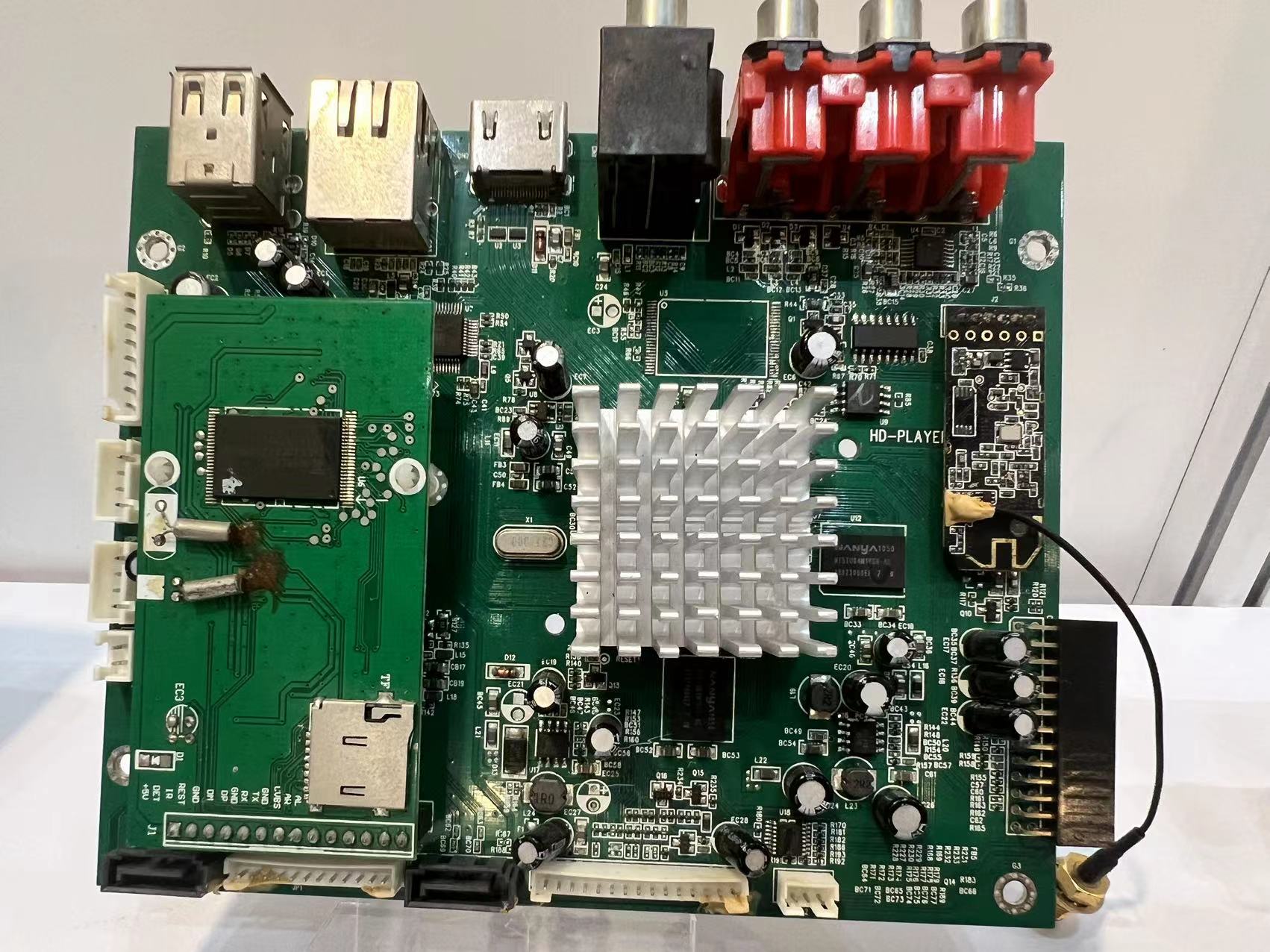

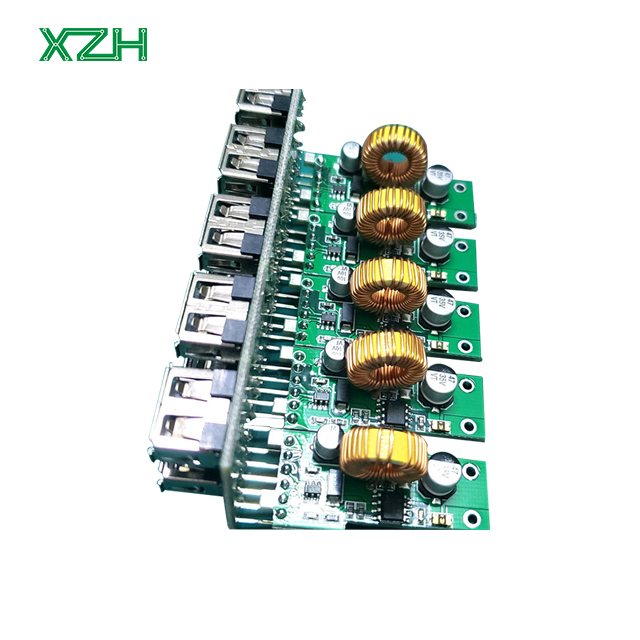

One-Stop PCB Fabrication and Assembly

One-Stop PCB Fabrication and AssemblyLayers40 LayersCopper Thickness0.5-6 OZMaterialFR4, HI-TG, FR06, Rogers, Taconic, Argon,Nalco,Isola and so onSolder Maskgreen, yellow, white, blue, black, redFinis...

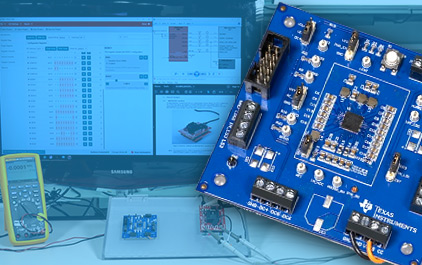

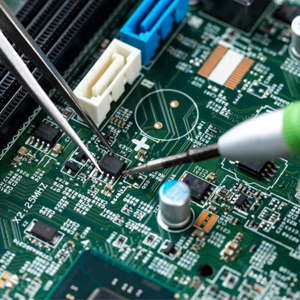

What is the advantage of SMT?

"SMT" is the abbreviation for "Surface Mount Technology".The advantage of SMT: The volume and weight of patch components are only about 1/10 of the traditional. Generally, aft...

OEM 3D Printer Printed Circuit Board Assembly Service

QualityISO, TS16949 and UL certified factory, manufactures RoHS compliant PCB products. Optimized supply chain management ensures good quality of...