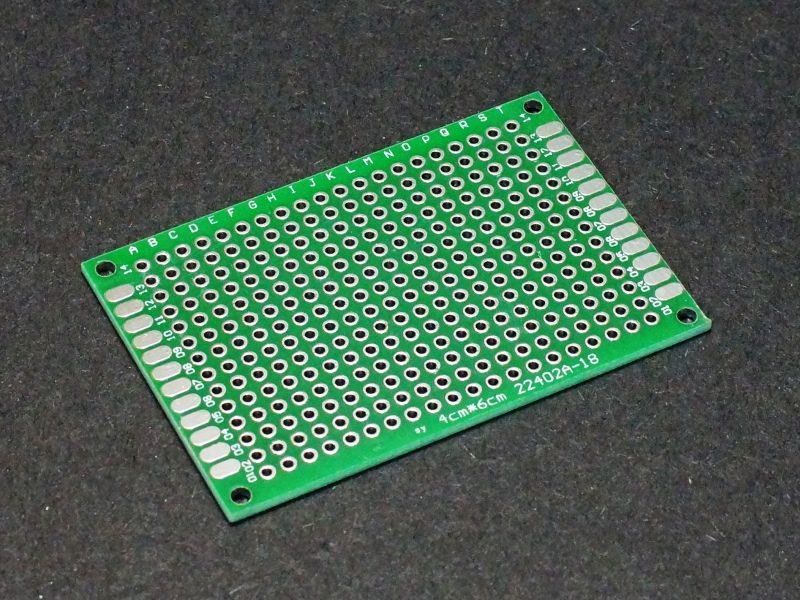

Printed Circuit Board

How to get your first Pcb prototype Manufactured?

If you are thinking about getting your first PCB Prototype manufactured, congratulations! We applaud you for your desire to innovate. If you don't quite know how to go about doing it, don't worry. There's a first time for everything, but first times can be tough. To help, we've put together this guide on getting from idea to PCB prototype.

First, let us say that you don't have to be an engineer to develop a new product. It doesn't hurt, but people with all levels of technical skill can become investors. Whether you are an entreneur, maker, inventor, start-up, or small company this post will help you understand the PCB prototyping process.

PCB Development

This post will assume that you are going to design the PCB yourself. Of course, you could always hire a freelance design engineer or design firm. Another option is to find someone who has engineering skills to become part of your team, with a stake in the eventual profits. If you are going to do the design work yourself, at the very least you should plan on getting an independent design review.

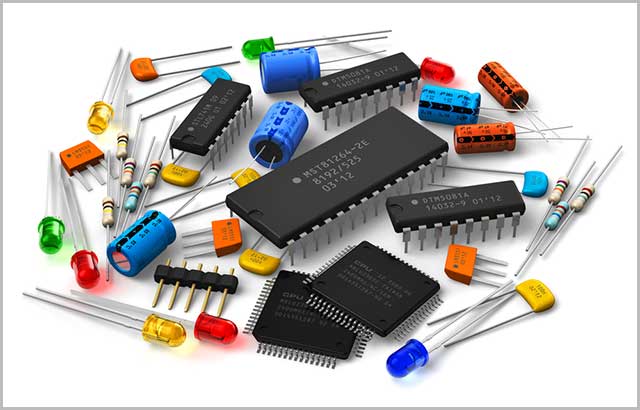

Core Components Selection

Step one is to determine which electronic components, such as microchips (integrated circuits), sensors, connectors, displays, and others will be needed based on the function of your PCB and the target price for your product.

You can source components on your own or choose a manufacturing partner that handles parts sourcing for you. This is a great way to eliminate some of the hassle and keep your costs as low as possible.

It is a good idea to create a detailed system block diagram. In most cases, you will have a master microcontroller with various components such as displays, memory, sensors, and so forth interacting with the microcontroller through various serial ports. With the block diagram, you’ll be able to determine the type and number of serial ports required easily. This will help you select the right microcontroller for your PCB.

Circuit Design (Schematic)

Next, it is necessary to create a schematic diagram or a diagram of the electronics design. Special electronics design software is used to create the schematic. There are many design applications to choose from. You can think of the schematic like the blueprint for a house. Generally, you’ll need a schematic circuit design for each block of your system block diagram. The schematic shows how every component connects.

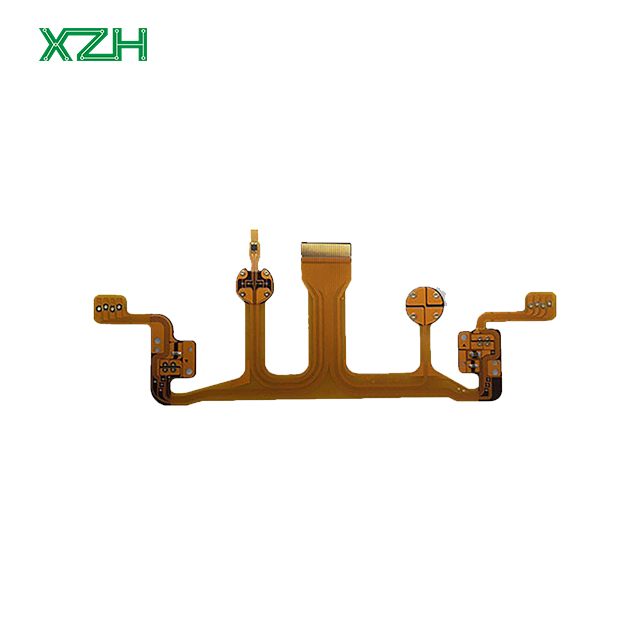

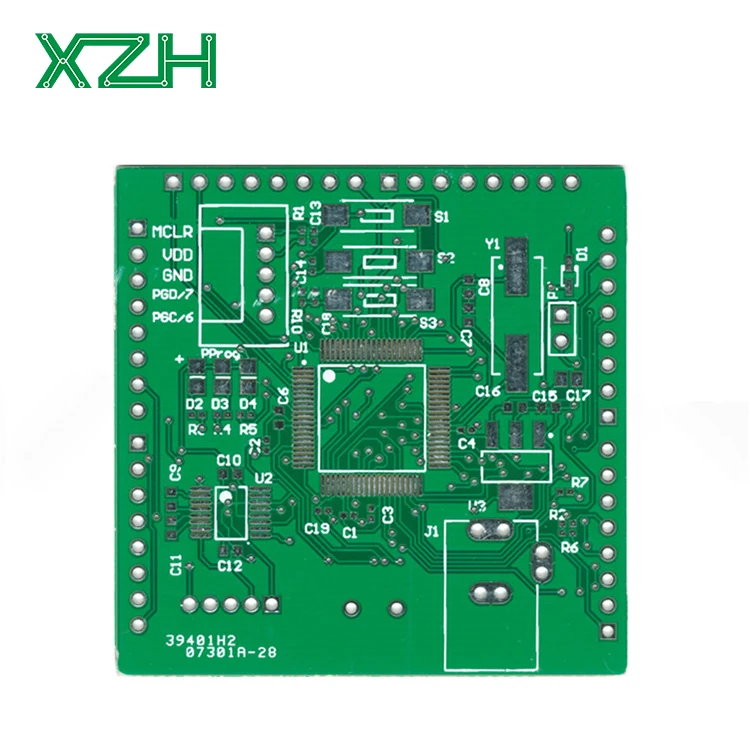

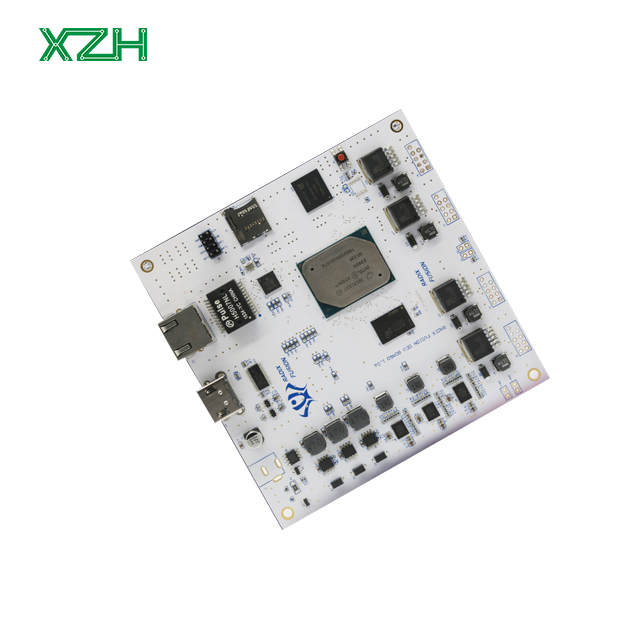

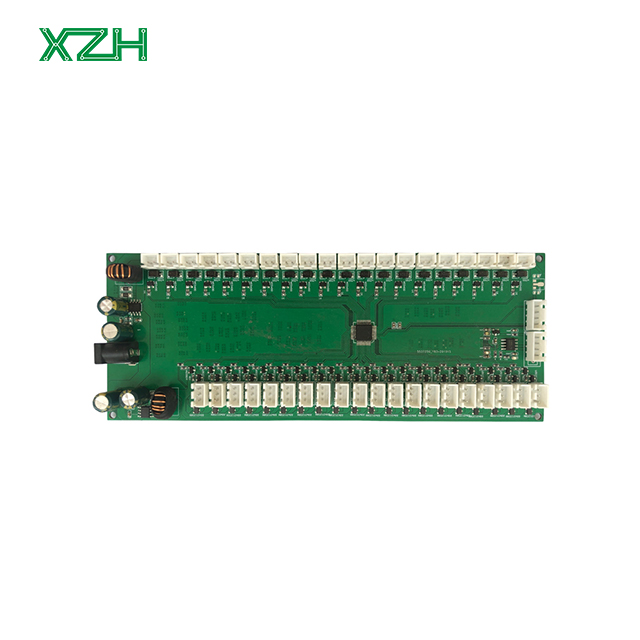

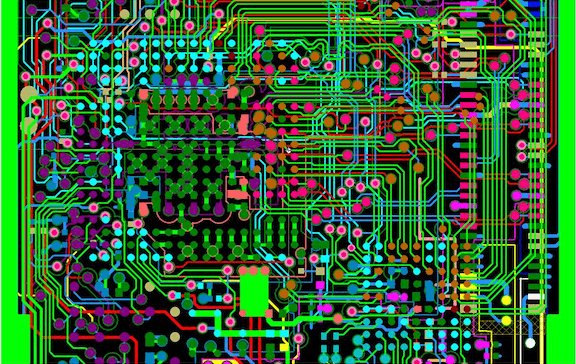

Printed Circuit Board Design

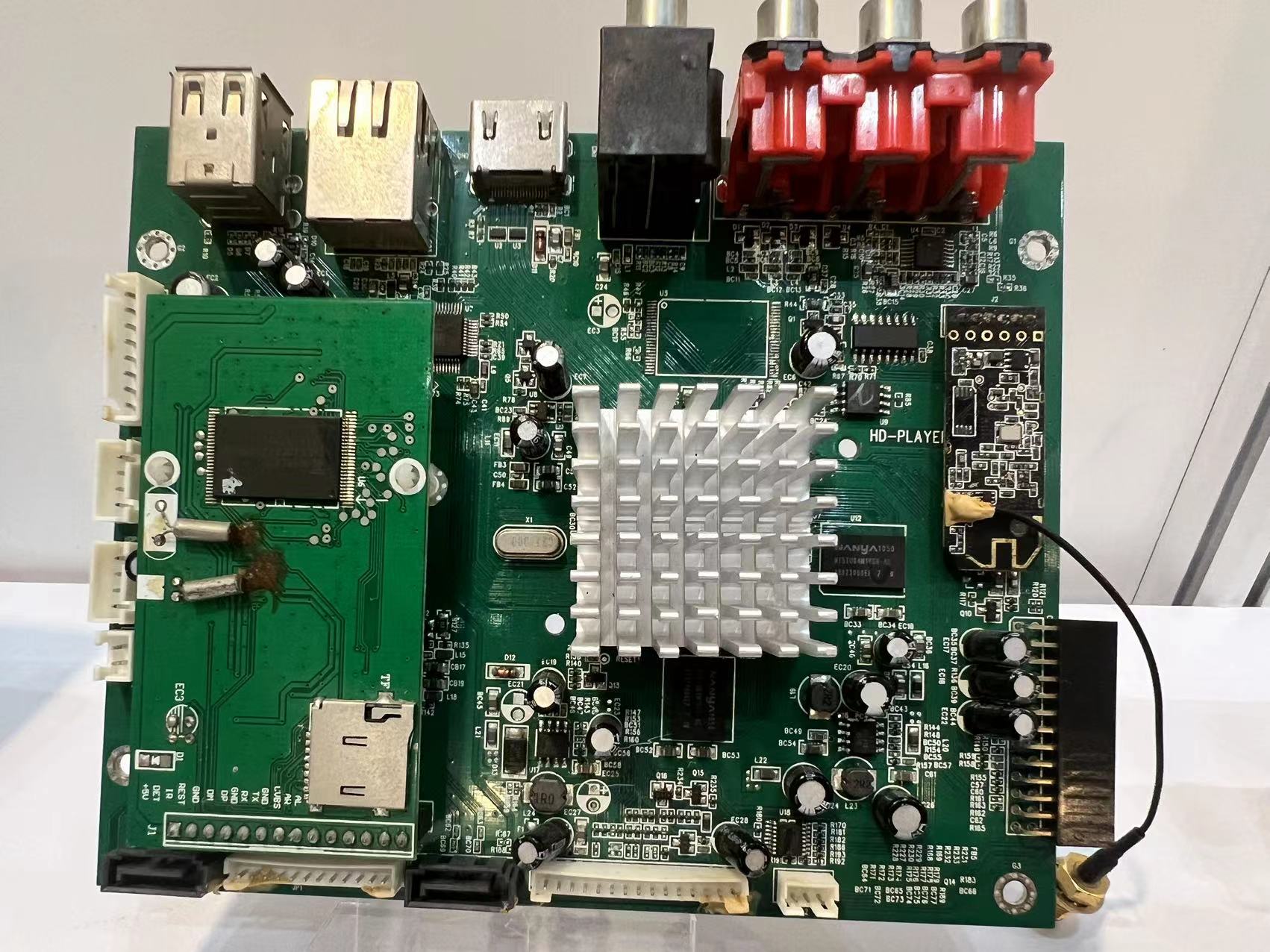

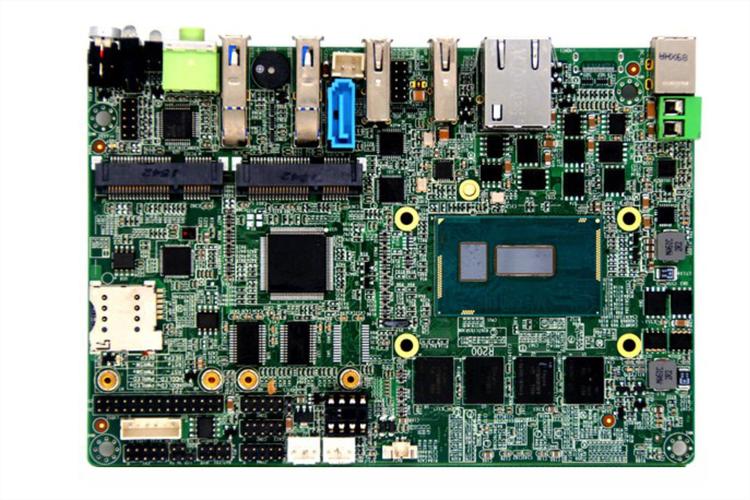

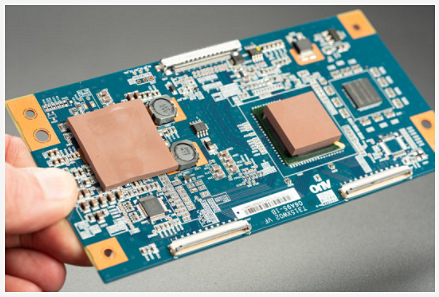

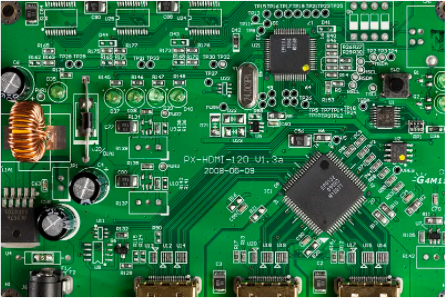

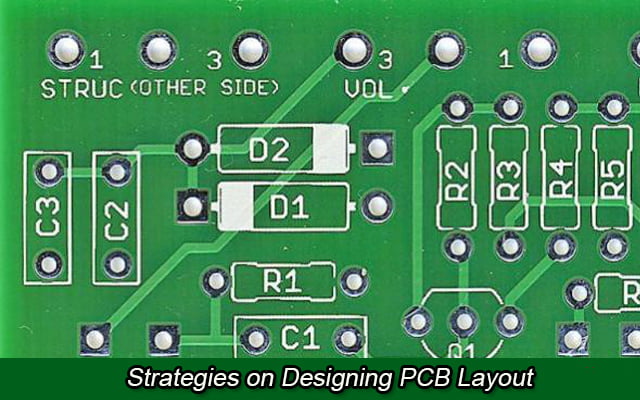

Following the creation of the schematic, you will be ready to create the design for the Printed Circuit Board (PCB) itself. The PCB is the physical board that contains and connects all of your electronic components. You can expect this to be the step that takes up the most time.

PCB Layout Product Design

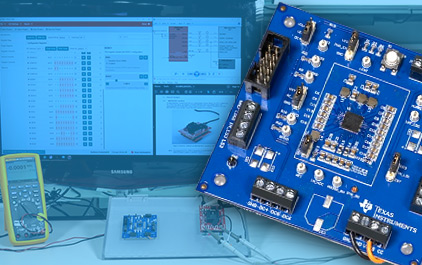

You can use the same software that you used to create your schematic diagram for the PCB design. It will have tools that verify that the PCB layout meets the design rules for the PCB process and that the PCB is in sync with the schematic.

Keep in mind that small products with tightly packed components will take longer to layout. Products that route lots of power, or involve wireless connectivity also increase the difficulty level of the PCB effort.

In most cases, the critical parts of PCB designs are the power routing, any high-speed signals (crystal clocks, etc) and any wireless circuits.

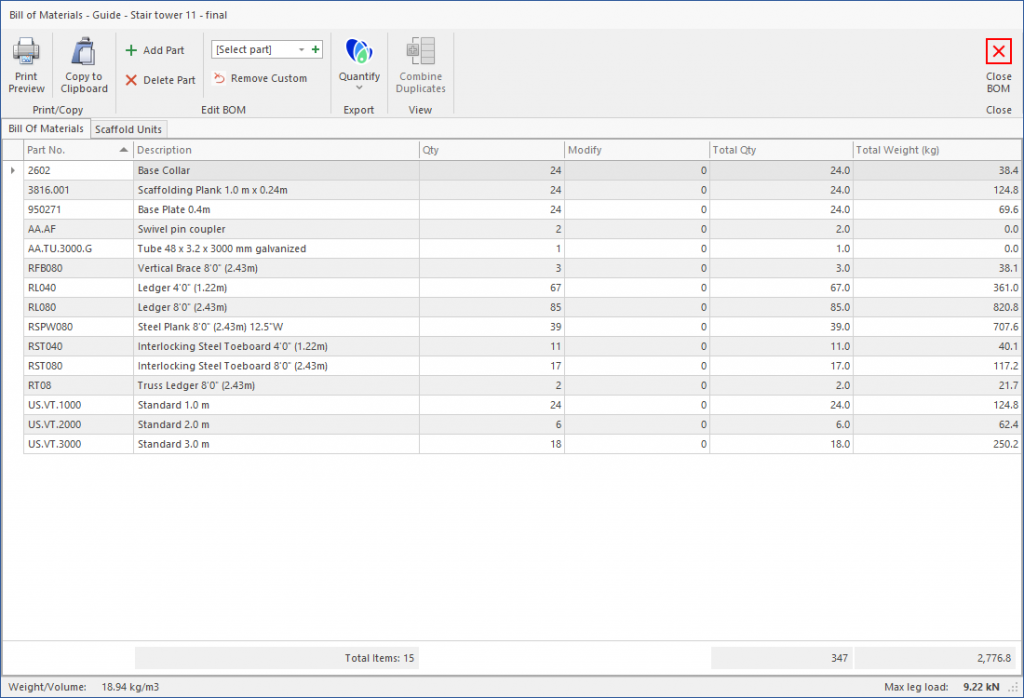

Bill of Materials (BOM)

Following the completion of the PCB layout, the Bill of Materials can now be generated. This is usually automatically created by the schematic design software. The BOM lists the part number, specifications, and quantity for each part.

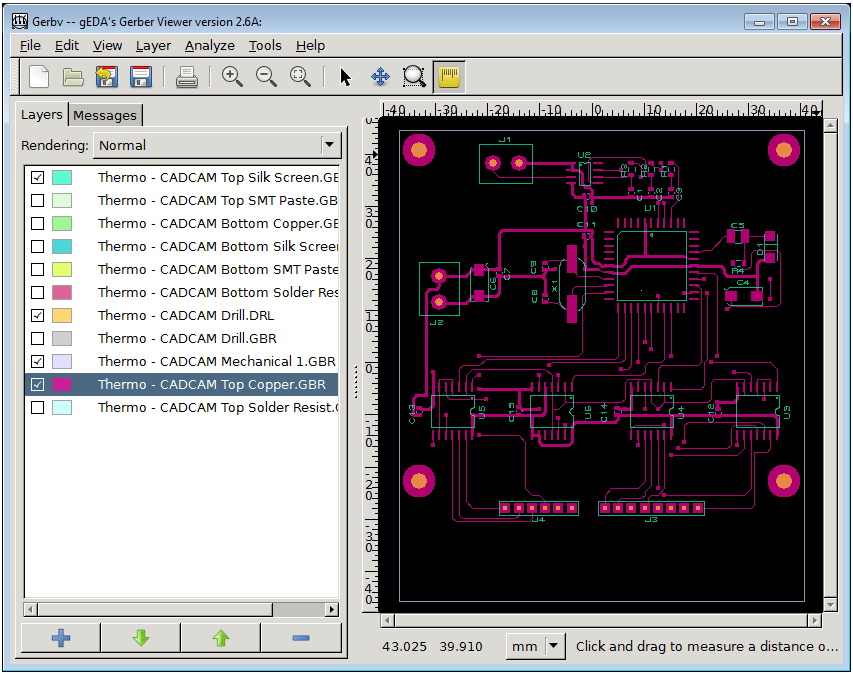

PCB Prototypes

There are two steps to creating PCB prototypes. The first is the production of the bare printed circuit board. The circuit design software will create a PCB layout format that has one file for each layer of the PCB. These files can be sent to the PCB Manufacturing partner that will be creating your prototype.

Once the board is created, all of the electronic components can be soldered onto the board. Your design software comes in handy again by creating an output file that shows the exact coordinates of each component. This allows for automation of the soldering.

Assess, Test, Repeat

Once you get your PCB back from the manufacture, it is time to see how it turned out. Don’t be surprised if your first prototype does not work as expected. It is perfectly normal to go through several iterations before a perfectly functioning board is achieved.

Be patient as you work to debug your PCB. Bugs by nature are unplanned, so it can be a time-consuming process to find the root of the problem and figure out how best to fix it.

Choose Your Partner Wisely

Those are the practical steps to designing and getting your first PCB manufactured. In closing, we’d also like to note that not all manufacturing partners are the same. In order to increase your odds of success choose one that:

Welcomes prototyping orders with open arms and reasonable prices

Offers instant, online quotes

Takes care of parts sourcing for you and offers discounts on the most popular components

Offers all the services you might need after your PCB is complete including electronic device assembly, inventory management, and fulfillment services

Provides an easy-to-use project management interface so that you can closely track the progress of your prototyping and production orders

We're not going to say that designing and getting your first PCB prototype manufactured is a walk in the park. As you can see, a lot of careful thought and attention to detail is required in order to achieve the results you want. But we know that you're up to the challenge and we are standing by to help if you are looking for a partner to go on the journey with you.

Related articles

PCB Design Service

PCB Design ServiceXZH Technology Co., Ltd was found in 2014.,with perfect quality assurance system and advanced test-analyzed instrument. We have rich experience in the production and development of v...

Prototype multilayer PCB

Prototype multilayer PCB...

The advantage of XZH's PCB

Why choose us?Online instant quote without hidden costQuick turn service with 24 hours build timeOver 7 years experience with trusted capabi...

Car Battery Charger PCB

Car Battery Charger PCBXZH Technology Co., Ltd was found in 2014.,with perfect quality assurance system and advanced test-analyzed instrument. We have rich experience in the production and development...

Gerber Design And Development Service

Gerber Design And Development Service XZH Technology Co., Ltd was found in 2014.,with perfect quality assurance system and advanced test-analyzed instrument. We have rich experience in the produc...

PCB Design

PCB DesignXZH Technology Co., Ltd was found in 2014.,with perfect quality assurance system and advanced test-analyzed instrument. We have rich experience in the production and development of voice rec...