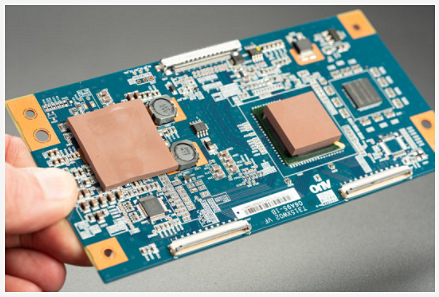

Printed Circuit Board Assembly

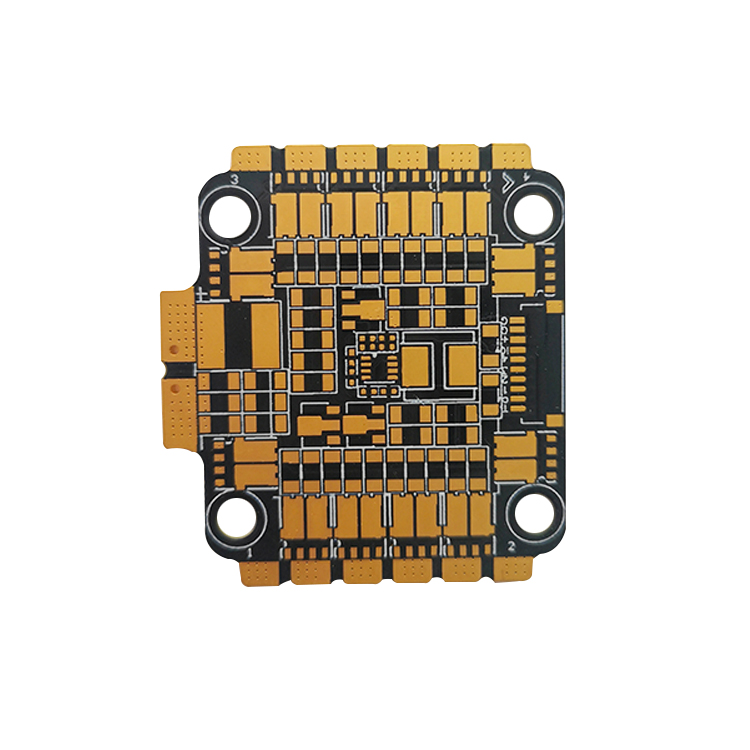

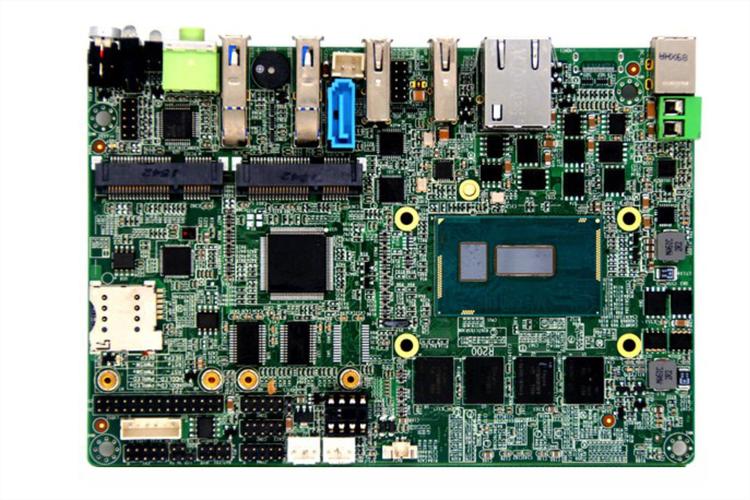

Professional HDI PCB Fabrication & manufacturing

XZH has the capabilities and experience to take on all jobs — including high-density interconnect (HDI) fabrication and manufacturing. HDI pcbs have become increasingly popular and are used in a wide variety of industries, including medical, military, and aerospace. They are found most notably in smartphones, tablets, and other digital devices.

As a leading HDI PCB manufacturer, we continue to invest in the most sophisticated production and testing equipment and technology. besides, we have the deep engineering experience to handle complex jobs with

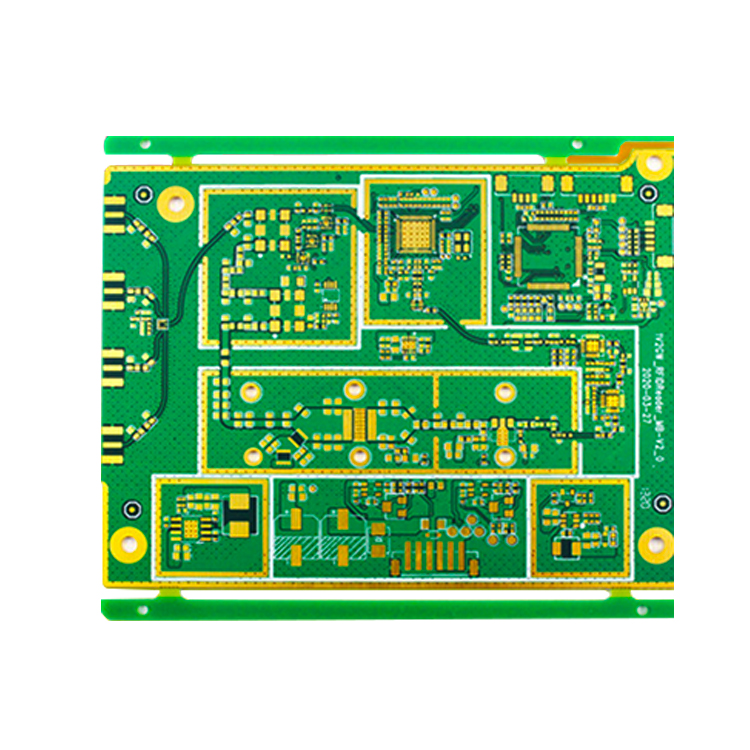

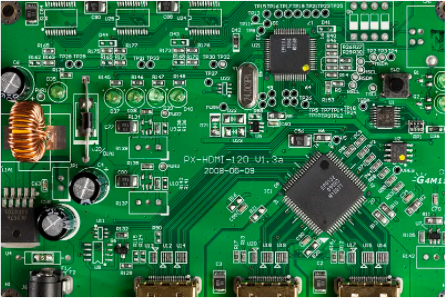

HDI Capabilities

HDI PCBs are characterized by thin lines, closer spaces, and more dense wiring, which allow for a faster connection while reducing the size and bulk of a project. These boards also feature blind and buried vias, laser-drilled microvias, sequential lamination, and via in-pads.

We use the most advanced equipment and technology, including laser direct imaging, to hold tight tolerances so that we can meet today’s HDI PCB requirements.

Our capabilities also include:

Back drilling – A method of disconnecting part of the plated through the hole from other layers inside, which is something many of our competitors don’t do.

Controlled depth drilling/milling

Buried capacitance – This technology can increase the performance of Printed Circuit Boards through improved signal integrity. This process incorporates a very thin dielectric layer that provides distributive decoupling capacitance.

Hole tolerances – With our advanced technology drilling equipment, we’re able to hold very tight hole tolerances and hole locations. This is important because these holes have multiple functions, including through-hole connector insulation and preventing signal leakage.

Fine pitch – Down to .3mm

Our experienced engineers have also worked with every type of PCB material, so they have the knowledge and expertise to provide recommendations and answer all of your HDI PCB questions. Most importantly, they know how to assist with manufacturability and the potential cost drivers of a project.

Related articles

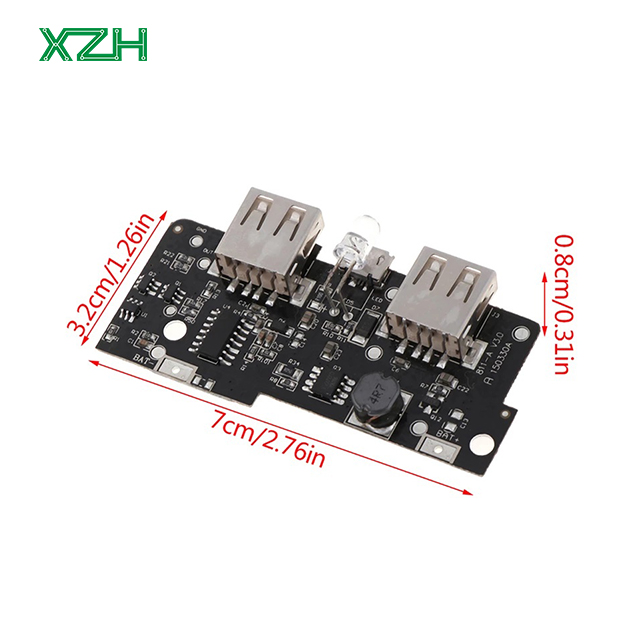

PCBA samples service

PCBA samples service...

How to Choose PCB assembly and PCBA manufacturer in shenzhen?

One-Stop OEM ServiceIf desired, we will source, organize and manage all aspects of the PCB design, so that your product meets all required standards and is fully optimized for easy and cost-effective...

Do you have Moq of pcb/pcba project?

Do you have the Moq of pcb/pcba project?In our company, there is no moq , you can choose samples to test the quality first, but our customers always choose 5 pcs to test....

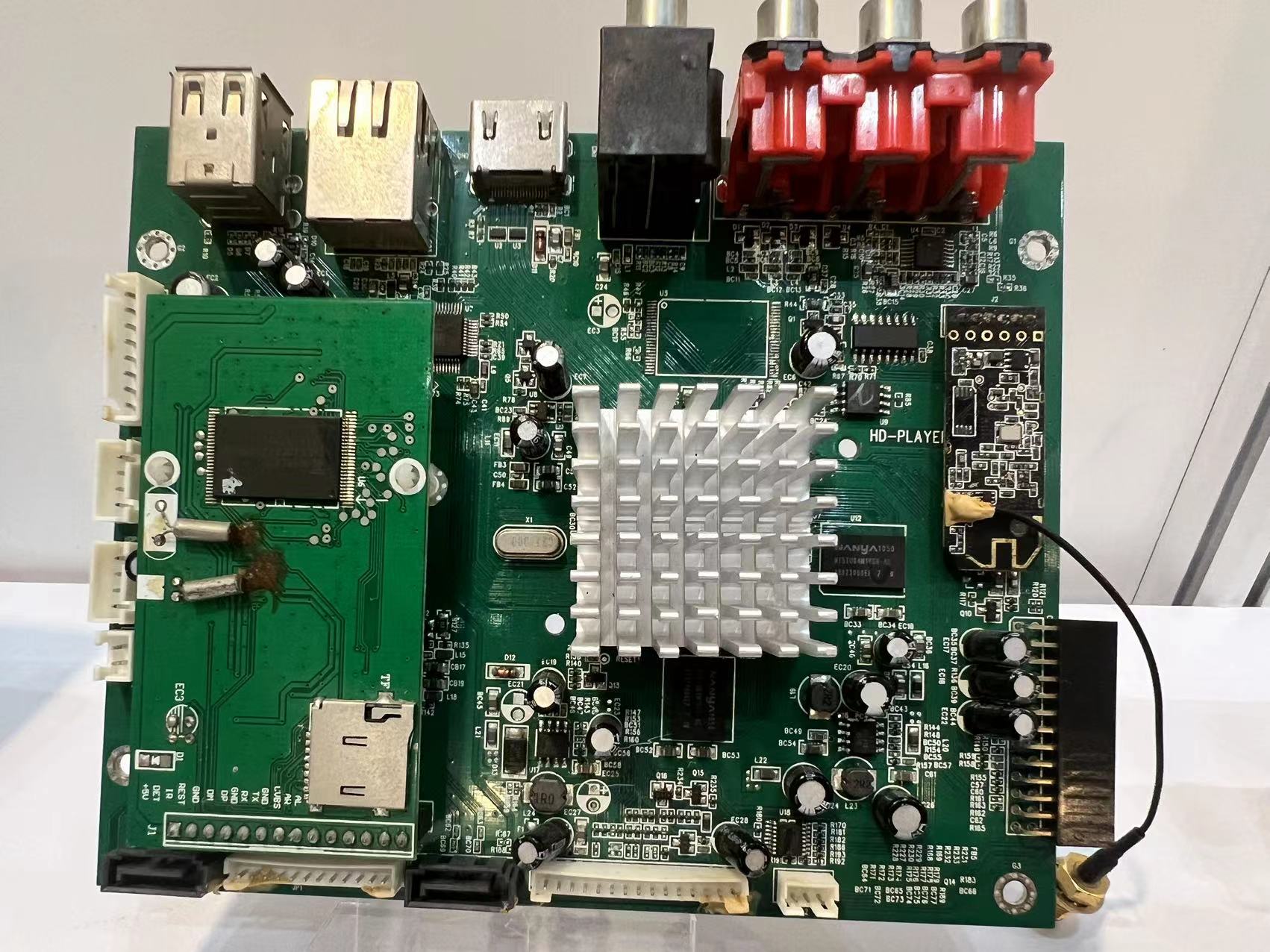

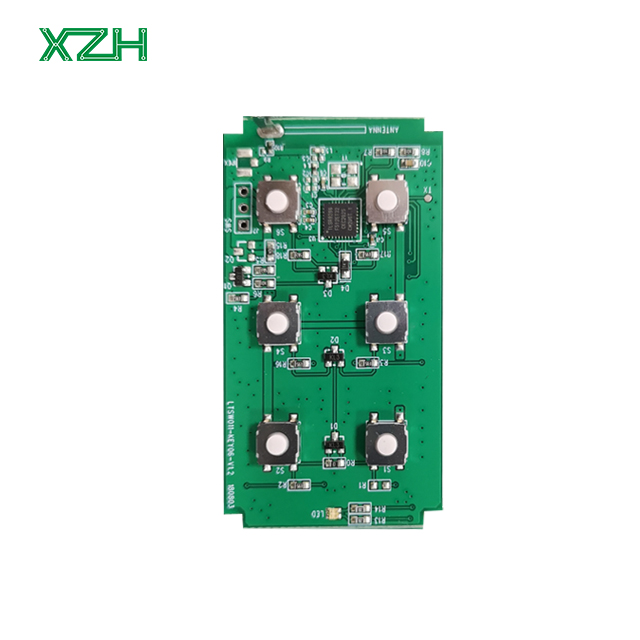

Customized Raspberry Pi PCBA

Customized Raspberry Pi PCBA...

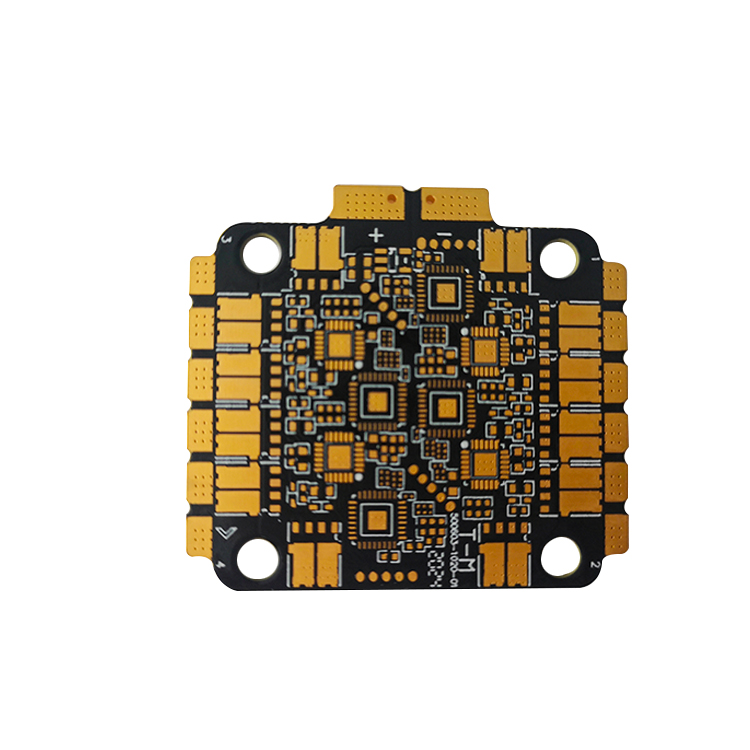

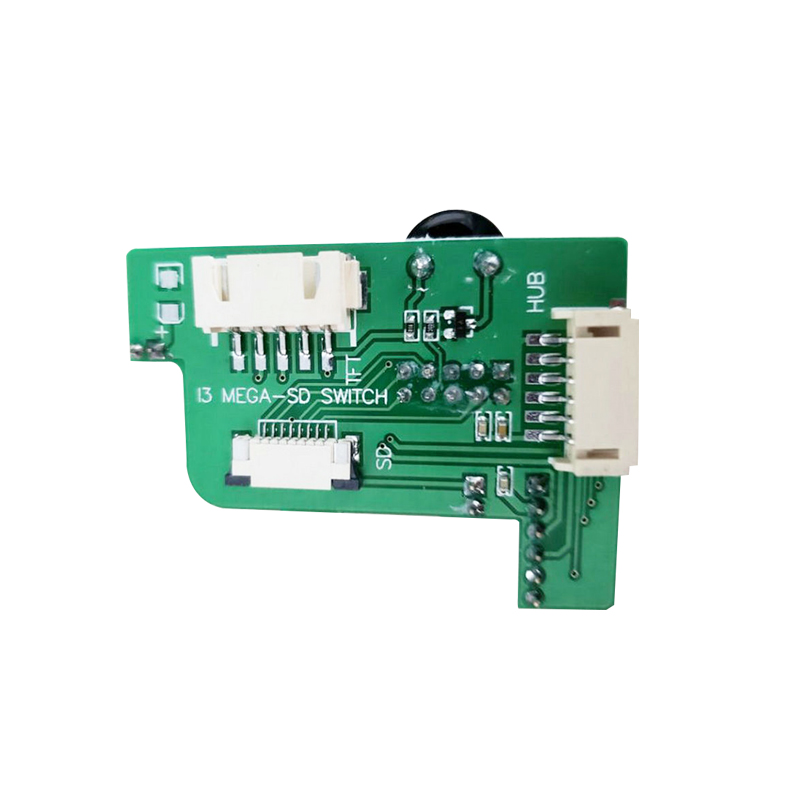

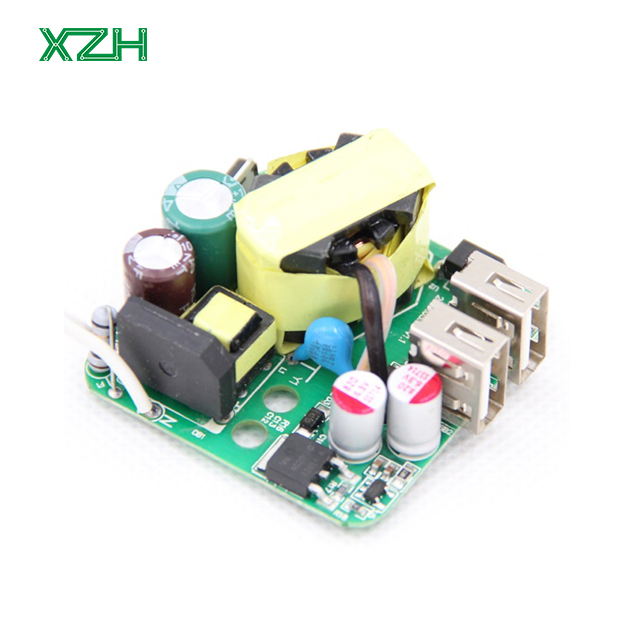

Antenna Amplifier circuit board

XZH Technology Co., Ltd was found in 2014.,with perfect quality assurance system and advanced test-analyzed instrument. We have rich experience in the production and development of voice recorder and...

12V 2A Lead-acid Battery Charger Protection Circuit Board

One-Stop OEM ServiceIf desired, we will source, organize and manage all aspects of the PCB design, so that your product meets all required standards and is fully optimized for easy and cost-effective...