Blog

As today’s electronics designs become smaller and more complex, more engineers are relying on Surface Mount Technology. After the 1980s, this technology became the preferred PCB Assembly technology in electronics manufacturing and hasn’t let up since.

Most components of the phone in your pocket, whether an iPhone 14 or a flip phone, were probably made via surface mount technology (SMT). Many of the components in your car or Uber ride today were likely made via SMT assembly.

So, what is SMT assembly, and why did this technology need to be created?

WHAT IS SMT ASSEMBLY: THE BASICS

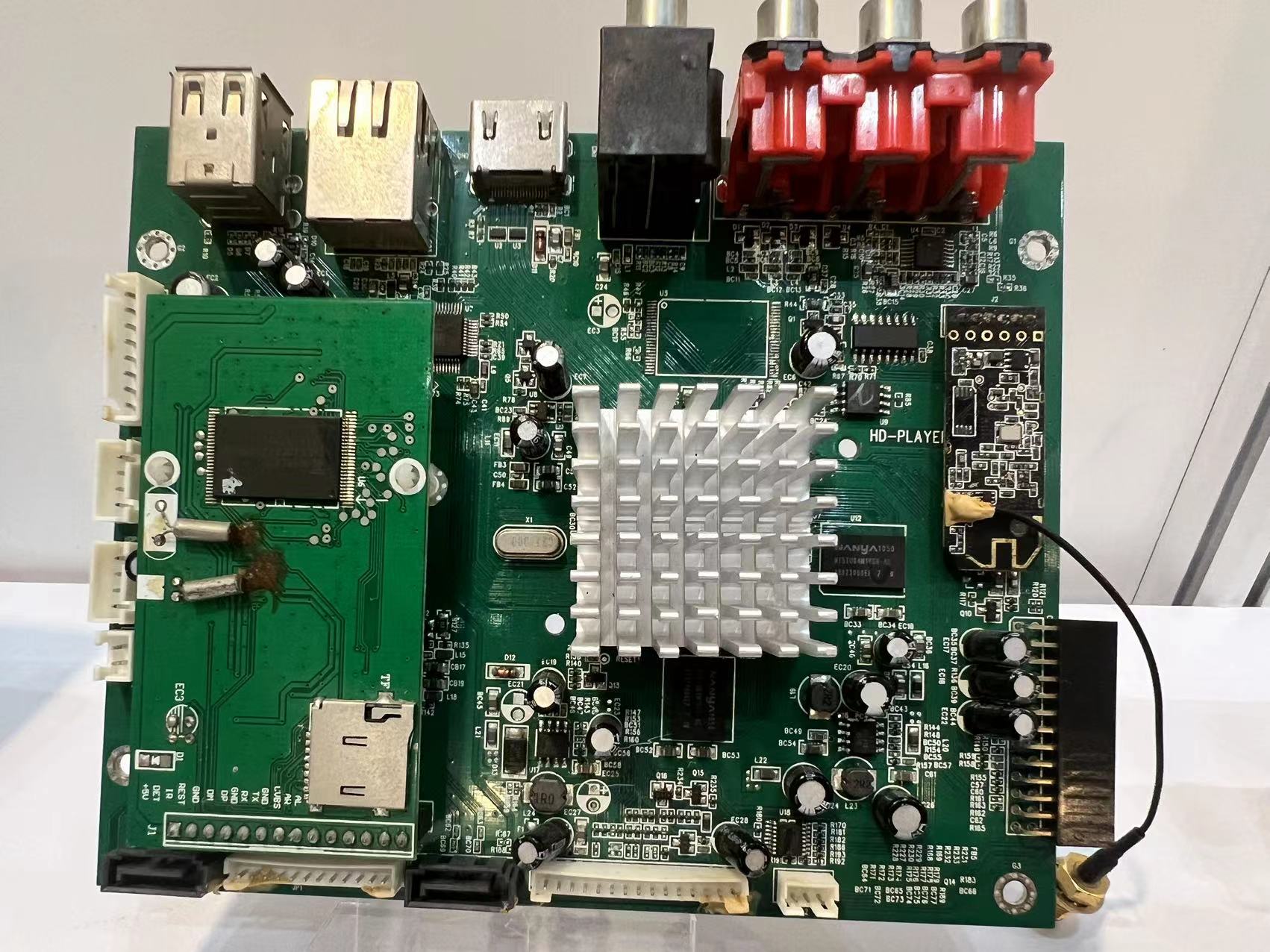

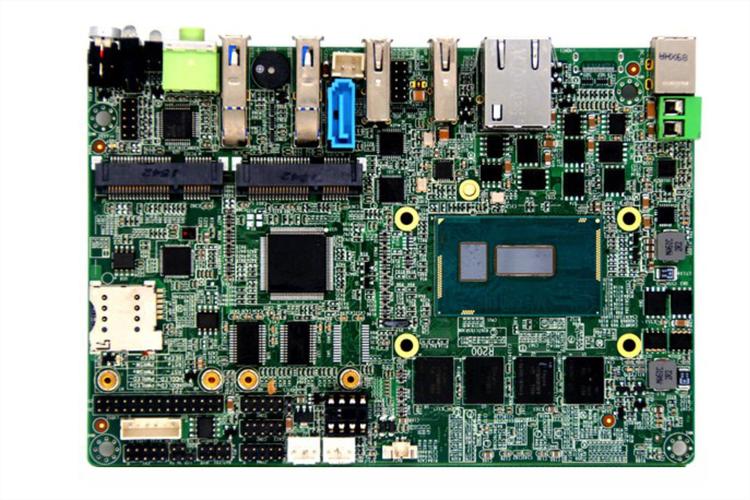

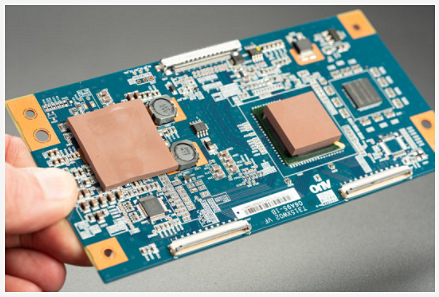

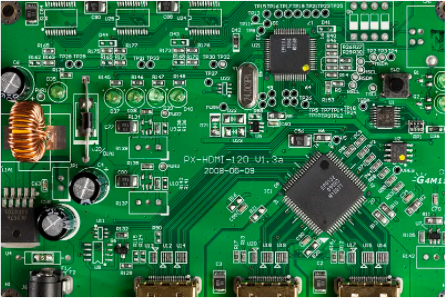

Surface mounting is a way to produce electronic circuits by placing components directly onto the board’s surface.

SMT assembly is an alternative to the through-hole method of PCB Manufacturing, which had its heyday in the 1970s and 1980s. As electronics manufacturing continued to gain momentum, a more efficient, better process became necessary. SMT assembly was born out of this need.

SMT assembly for PCBs has a broad range of uses. It also has a few limitations your design team should consider.

SURFACE MOUNT TECHNOLOGY ADVANTAGES

Just like with through-hole, there are both pros and cons involved with SMT. Let's start with some of the advantages of SMT assembly:

1. AFFORDABILITY

One of the reasons SMT assembly was conceived was to reduce manufacturing costs.

SMT requires far fewer holes to be drilled into the circuit board. This lowers the costs of processing and handling significantly.

Finally, SMT is more capable of producing high volumes, allowing for a better per-unit cost.

2. EFFICIENCY

Another benefit of SMT assembly is that it uses circuit board space much more efficiently. Thanks to SMT assembly, engineers can now finagle complex electronics into smaller assemblies.

In addition to more efficiently using the space on a PCB, SMT assembly is much faster, allowing manufacturers to increase total output. To put this in perspective, something that might have taken 1-2 hours to perform via through-hole takes 10-15 minutes via SMT assembly.

3. SIMPLICITY

In through-hole assembly, lead wires pass through the holes to connect components. Because SMT components are soldered right onto the PCB, the overall makeup is far less complex.

4. LESS PRONE TO ERROR

SMT assembly is very reliant on machines, and not so much on us humans. SMT is a process that's less prone to error because it's almost entirely automated.

USES FOR SURFACE MOUNT TECHNOLOGY

SMT assembly was born as a way to create a better, more powerful electronic product.

One look around your office or living room will show you several common surface mount technology applications. Basically, turn to surface mount PCB assembly whenever you need a product that’s:

● Smaller

● Lighter

● Faster

● More powerful

While through-hole is still used in certain applications or even certain locations on a board, SMT assembly has largely taken over.

DISADVANTAGES OF SURFACE MOUNT TECHNOLOGY

As is the case with all manufacturing processes, there are some disadvantages to SMT assembly. The biggest is that it requires much more attention to detail than through-hole assembly. Even with the process largely automated, your design parameters still have to be met to produce a quality end product. This largely falls on the shoulders of the designer and the electronics contract manufacturer.

Trouble can also arise when SMT is used to place components to a PCB that will function in conditions that will involve:

● Mechanical stress

● Environmental stress

● Temperature stress

This problem can be mitigated by blending SMT with through-hole processes to get the benefits of both. That’s right -- you can use both on the same board!

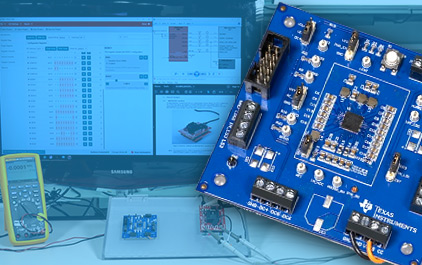

Xinzhanhong is a professional Printed Circuit Board Manufacturing and assembly factory, providing one-stop PCBA customization service for customers.

If you are looking for a professional PCB manufacturer partner in China,please contact us!.We will get in touch with you as soon as possible!

| List | Mobile number | |

| Rita | +8615999583126 | xzh01@xzhpcba.com |

| Chloe | +8613424351747 | xzh03@xzhpcba.com |

| Cindy | +8615820455581 | xzh05@xzhpcba.com |

| Winnie | +8615999583192 | xzh06@xzhpcba.com |

| Maple | +8613423740397 | xzh07@xzhpcba.com |

Address:5/F,B5 West Building,Hengfeng Industrial Town ,Xixiang, Baoan District, Shenzhen, Guangdong, China.

Related articles

How can we test a pcb?7 pcb testing methods you need to know

When you order printed circuit boards (PCB), you know the pricey consequence of failure. The last thing you need financially is for your PCBs to suddenly drop dead -- or to have a shortened life span...

How do you test a PCB with a multimeter?

Multimeter and circuit boards are two things that go hand in hand. While the former is used for troubleshooting, circuit boards, on the other hand, are used in varied electrical equipment. One of the...

The difference between PCBA and PCB

PCB and PCBA are related terms in the field of electronics, but they refer to different things:1.PCB (Printed Circuit Board):A PCB, or Printed Circuit Board, is a flat board made of a non-conductive m...

what is as9100 certification?

When an OEM is sourcing out work -- let alone aerospace electronics manufacturing -- it’s likely to come across companies that boast about all sorts of certifications and capabilities.One certificatio...

Why PCB Testing Is Necessary?

Why PCB Testing Is Necessary?Testing is a crucial part of the manufacturing process for PCBs. When PCB testing is conducted throughout the production cycle, it can help save money and prevent iss...

What does PCBA mean?

PCBA stands for Printed Circuit Board Assembly. Up to this meaning, it’s all fine. But the real problem starts right from here. Many, in fact, most people don’t understand the true meaning and purpose...