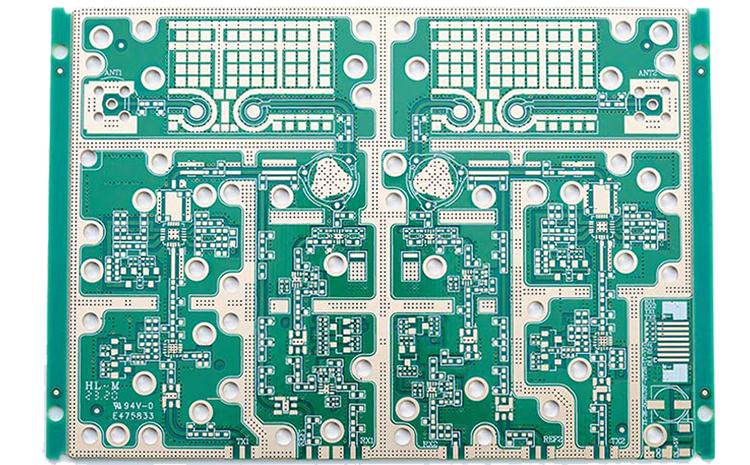

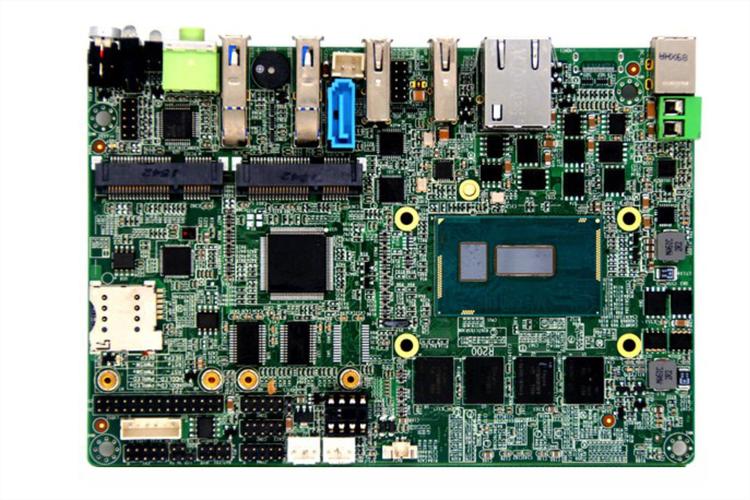

Printed Circuit Board

Interesting PCB knowledge

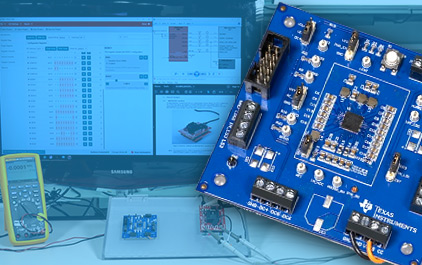

Difference between SMT is a fast, fully automated process that improves component mounting accuracy, reduces manual labor, provides consistent quality and reduces costs. We have accumulated a lot of knowledge about SMT. Today, we will present the advantages and scope of the through-hole to SMT conversion.

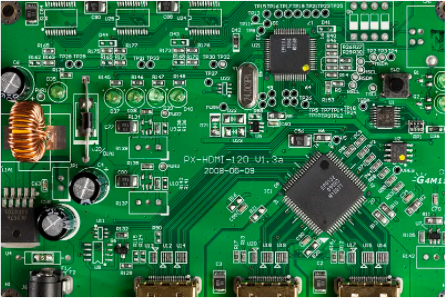

What are the advantages of through-hole to SMT conversion?

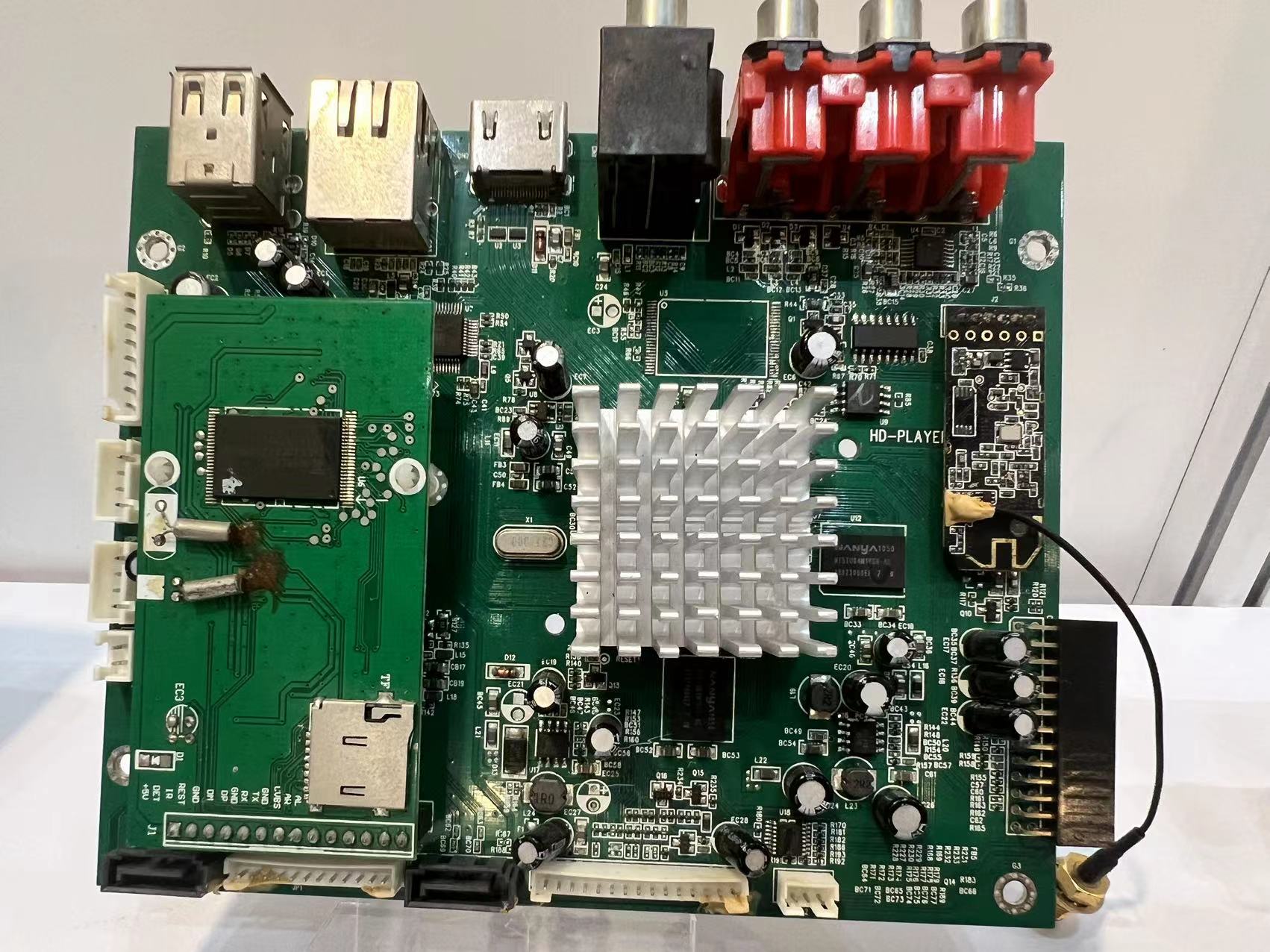

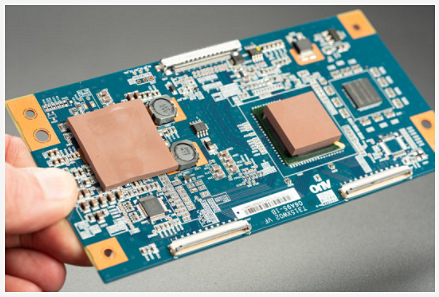

Surface mount components (frequently called SMD-surface mount devices) are smaller and lighter than through-hole components. This allows for lightweight plates and higher density parts.

SMT does not require pre-drilled plates, which reduces manufacturing time and costs. The process is also fully automated, enabling the rapid production of extremely accurate and repeatable boards, further reducing costs.

Since the component leads cannot be threaded through the board, the components can be mounted on either side of the board. This opens up additional design possibilities and additional functionality can be packed into the same area of the board.

manufacturers stopped using various through-hole assemblies, and most state-of-the-art assemblies are incompatible with through-hole mounts. SMDS is also generally less expensive than similar products with pass-through holes.

Automatic assembly improves installation reliability and reduces errors. It also allows for a more thorough and accurate test of the plates.

What is involved in the through-hole for SMT conversion?

When evaluating the product for conversion, we identify all potential issues that may affect the board, such as:

1. Product end-use (especially temperature and temperature cycle)

2. Mechanical constraints (form factor, vibration, etc.)

3. Component voltage, current and rated power

4. Component availability

5. programming and testability issues?

Related articles

How to clone your PCB board in XZH?

1. What is needed for PCB & PCBA quotation in XZH PCBA?XZHPCBA: For PCB: Quantity, Gerber file and technic requirements(material,size, surface finish treatment, copper thickness, board thickness)....

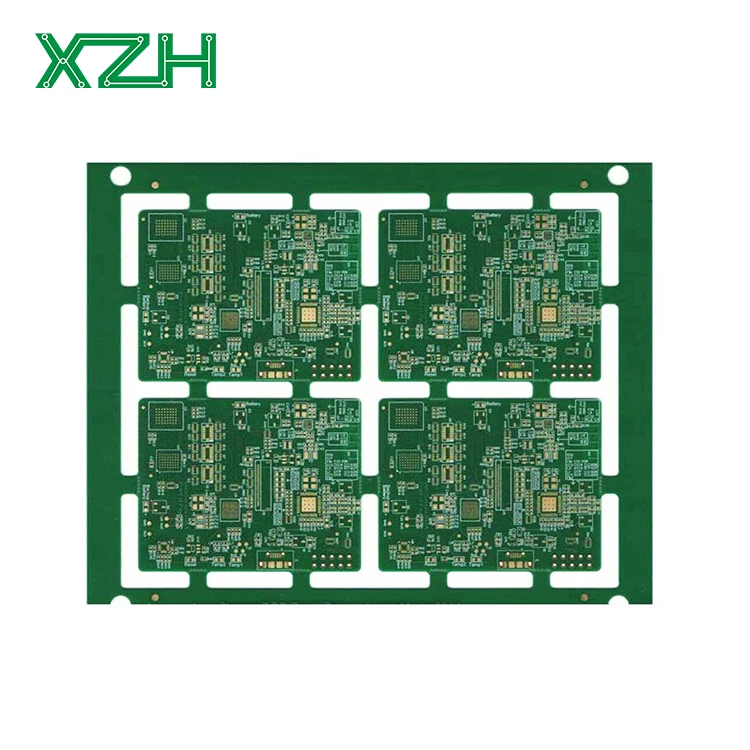

Heavy Copper PCB

XZH Technology Co., Ltd was found in 2014.,with perfect quality assurance system and advanced test-analyzed instrument. We have rich experience in the production and development of voice recorder and...

Inverter Refrigerator PCB

Inverter Refrigerator PCBXZH Technology Co., Ltd was found in 2014.,with perfect quality assurance system and advanced test-analyzed instrument. We have rich experience in the production and developme...

Smart Home Appliance Printed Circuit Board

Smart Home Appliance Printed Circuit BoardXZH Technology Co., Ltd was found in 2014.,with perfect quality assurance system and advanced test-analyzed instrument. We have rich experience in the product...

Experience PCB manufacturer in China

Why choose us?Online instant quote without hidden cost Quick turn service with 24 hours build timeOver 7 years experience with tru...

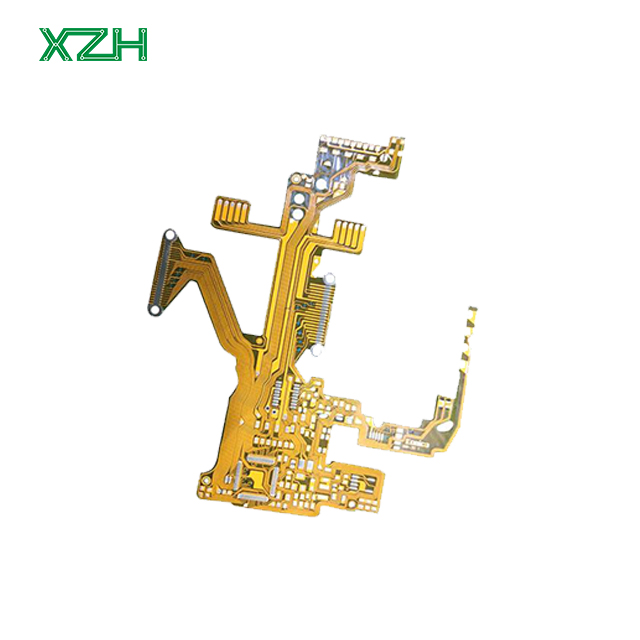

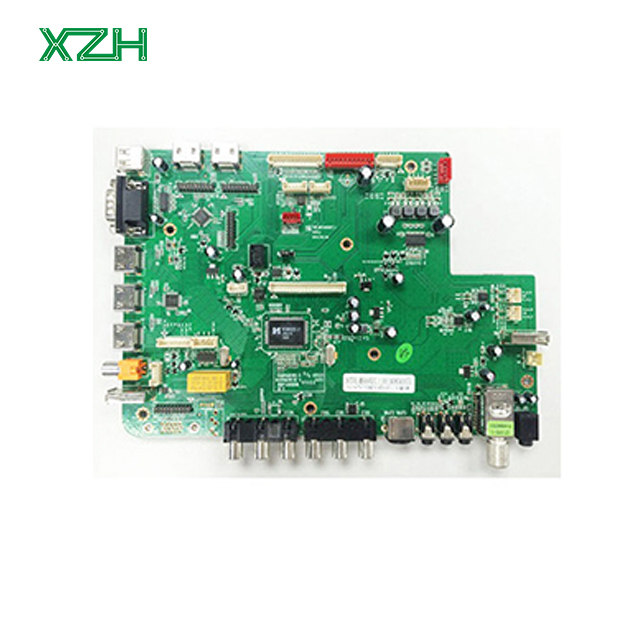

Lakoni Tv Pcb

Lakoni Tv PcbXZH Technology Co., Ltd was found in 2014.,with perfect quality assurance system and advanced test-analyzed instrument. We have rich experience in the production and development of voice...